Choosing the Best Flexible PCB Manufacturer

Printed circuit boards (PCBs) are essential for electronic devices, providing connectivity between components. Flexible PCBs offer versatility, being easily bent or twisted without losing functionality. When selecting a flexible PCB manufacturer, consider the following:

1. Manufacturing Facilities

- Ensure the manufacturer has advanced facilities for flexible PCB fabrication.

- Investing in modern equipment indicates a commitment to quality.

2. Skilled Technicians

- Look for manufacturers with experienced technicians specialized in flexible PCB production.

- Expertise in the manufacturing process is crucial for high-quality results.

3. Quality Standards

- Choose a manufacturer that meets quality criteria like durability, high-density design, and conductivity.

- Verify certifications such as UL, ISO, and IPC compliance for quality assurance.

4. Customization and Shape Capabilities

- Ensure the manufacturer can produce flexible PCBs in the specific shapes required.

- Adaptability to different shapes is crucial for various applications.

5. Cost Consideration

- Find a balance between quality and cost to optimize your investment.

- Quality manufacturers can help reduce production costs through efficient processes.

6. Prototyping for Success

Before full production, ensure the manufacturer provides prototypes to guarantee functionality. Prevent costly malfunctions in electronic devices by verifying PCB performance.

Benefits of Working with Top Flexible PCB Manufacturers

- Top flexible PCB manufacturers offer mock-ups for testing before final production, allowing for customer feedback and adjustments.

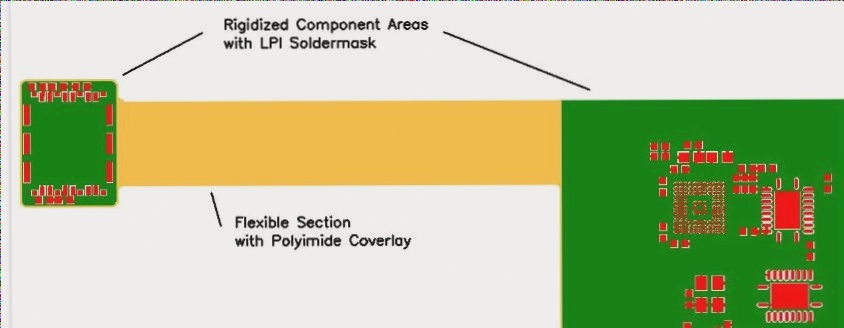

- Manufacturers can provide various types of flexible circuit boards, including single-sided, double-sided, and multilayer PCBs.

- Using appropriate materials in the flexible PCB structure is essential for functionality.

- Testing is crucial to ensure the integrity of flexible PCBs and detect defects early.

- China is a leading hub for high-quality flexible circuit board manufacturing, offering great value.

- China’s PCB manufacturing capabilities are advanced, driven by innovation and quality commitment.

Choose a manufacturer that can handle different component types and conduct various tests to deliver functional and reliable flexible PCBs.