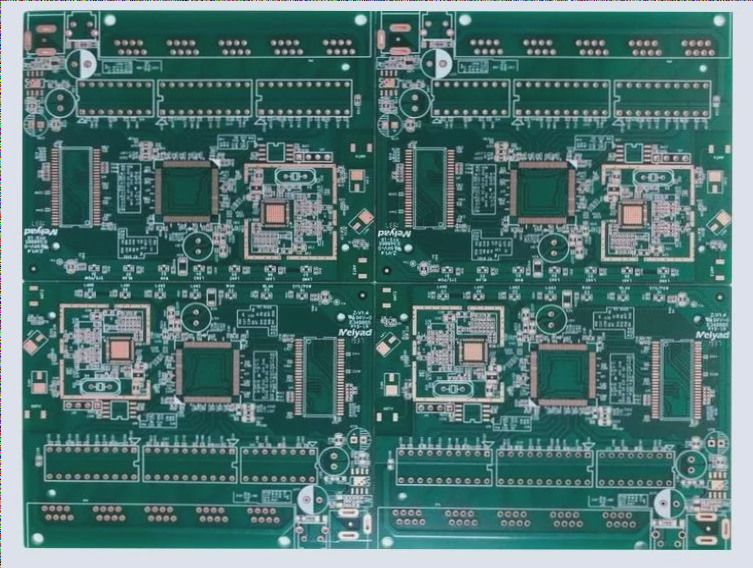

10 Effective Methods for Circuit Board Repair and Inspection

-

Offline Measurement

Check the DC resistance values between pins of the circuit board to determine functionality by comparing with known normal values.

-

Online Measurement

Measure voltage, resistance, and current values at each pin while the board is operational to assess its condition.

-

Substitution Method

Replace the board under test with a known-good board to identify and repair any issues.

-

Separation Test

Isolate faulty circuit sections to locate and repair faults through a systematic inspection process.

-

Signal Injection

Inject test signals into circuit stages to pinpoint fault locations and analyze causes.

-

Intuitive Check

Use human senses for basic equipment failure detection without the need for tools.

-

Signal Tracking Method

Step-by-step quantitative checks with test signals and tools to identify fault locations.

-

AC Short Circuit Method

Bypass circuit sections with capacitors to identify power interference and parasitic oscillations.

-

Parametric Test

Measure voltage, current, and component values to analyze electronic circuit parameters.

-

Waveform Observation Method

Analyze waveform differences using an oscilloscope to diagnose faults and plan repairs.

Additional Insights:

For effective PCB maintenance, it is crucial to store boards properly. Vacuum packaging, temperature, and humidity control are essential factors to ensure optimal performance and longevity of circuit boards. Proper storage conditions and maintenance can significantly impact the lifespan and functionality of PCBs.