PCB Component Layout Best Practices

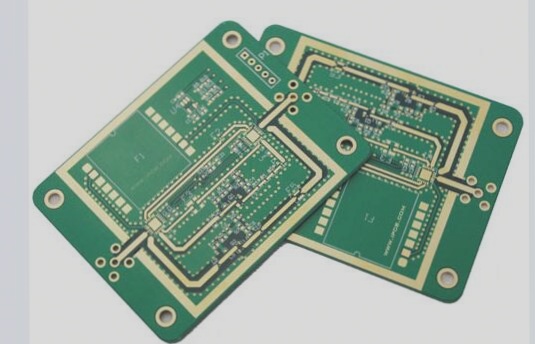

1. Basic Rules of PCB board Component Layout

- Consider circuit modules with components of the same function densely concentrated.

- Separate digital and analog circuits.

- Avoid mounting components near non-mounting holes and mounting holes.

- Avoid vias below horizontally mounted components.

- Maintain a 5mm distance between outer components and the board edge.

- Keep a 2mm distance between the outer pad of a mounted component and adjacent components.

- Avoid contact between metal shell components and other parts.

- Distribute heating elements evenly and keep them away from wires.

- Arrange power sockets around the printed board.

- Align IC components on one side with clear polarity markings.

- Ensure proper wiring density on the board.

- Avoid through-holes on patch pads.

- Ensure consistency in patch alignment and polarity marking.

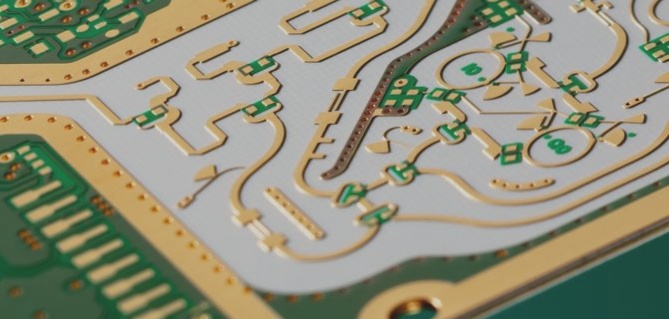

2. Component Wiring Guidelines

- Avoid wiring within 1mm of the PCB edge and around mounting holes.

- Maintain specific widths for power and signal lines.

- Ensure proper dimensions for via holes and component pads.

- Radial arrangement for power and ground wires.

- Avoid looping signal wires.

3. Enhancing Anti-Interference and EMC

Strategies to improve anti-interference and electromagnetic compatibility in electronic product development:

- Pay attention to systems with high clock frequencies and fast bus cycles.

- Address systems with high-power drive circuits.

- Focus on systems with weak analog signal circuits.

Tips for reducing noise and interference:

- Opt for low-speed chips when possible.

- Use resistors in series to reduce edge transition rates.

- Provide damping for components like relays.

- Utilize clock generators meeting system requirements.

- Keep clock wires short and ground clock areas.

The Best Practices for PCB Layout

- Place the I/O drive circuit close to the edge of the printed board to minimize signal travel time.

- Filter incoming signals and those from high-noise areas to improve signal quality.

- Utilize serial terminal resistance to reduce signal reflection.

- Connect unused ends of MCD to high, ground, or define as output.

- Ensure integrated circuit ends meant for power supply ground are connected.

- Avoid leaving input terminals of unused gate circuits floating.

- Ground the positive input terminal of unused operational amplifiers and connect the negative input terminal to the output terminal.

- Prefer 45-fold lines over 90-fold lines on printed boards to reduce external emission and signal coupling.

- Divide the printed board based on frequency and current switching characteristics.

- Use single-point power supply and grounding for boards, ensuring thick power and ground lines.

- Keep clock, bus, and chip select signals away from I/O lines and connectors.

- Separate analog voltage input and reference voltage terminals from digital circuit signal lines.

- Unify digital and analog parts for A/D devices rather than crossing them.

- Ensure clock lines are perpendicular to I/O lines to minimize interference.

- Keep component pins and decoupling capacitor pins as short as possible.

- Use thick lines for key signals and add protective ground on both sides.

- Avoid routing wires under quartz crystals and noise-sensitive devices.

- Avoid forming current loops around low-frequency circuits in weak signal circuits.

- Minimize loop areas for any signal routing.

- Include one decoupling capacitor per IC and add high-frequency bypass capacitors near electrolytic capacitors.

- Opt for tantalum or polycooled capacitors over electrolytic ones for circuit charge and discharge energy storage.

- Ground the case of tubular capacitors on the PCB board.