Benefits of 12-Layer Rigid-Flex PCBs

- Enhanced Reliability: Combining hardware and software results in stable and dependable performance.

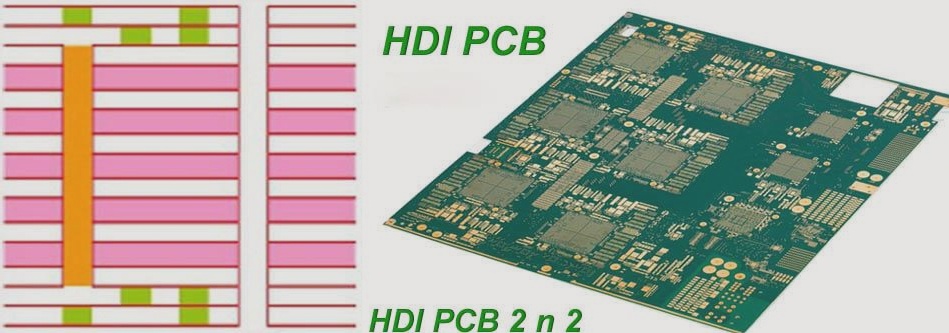

- Increased Integration: Higher layer count allows for more components in a smaller space.

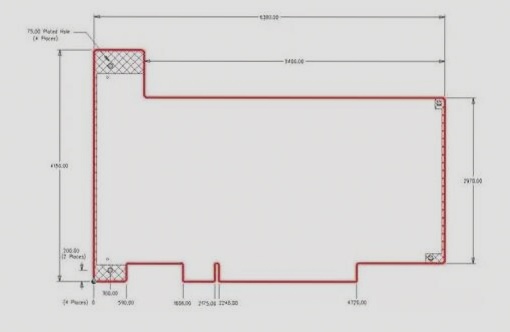

- Flexible Design Options: Flexible PCBs conform to complex layouts effectively.

- Space Efficiency: Consolidating functions saves space and reduces device size.

- Improved Performance: Superior electrical and mechanical characteristics meet stringent requirements.

- Reduced EMI: Minimized electromagnetic interference ensures cleaner signals.

Additional Advantages:

- Better Heat Dissipation: Integrated software and hardware disperse heat effectively.

- Higher Anti-Interference Ability: Improved shielding enhances resistance to interference.

- Longer Lifespan: Mechanical and electrical enhancements extend the board’s life.

- Faster Transmission Speed: Improved signal transmission enables faster data speeds.

Key Considerations:

- Material Selection and Design: Use high-quality materials and meticulous design for optimal performance.

- Quality Control: Rigorous testing ensures connectivity and electrical performance.

- High-Density Wiring: Advanced CAD software is essential for reliable signal transmission.

- Interlayer Insulation: Prevent electrical interference with proper insulation.

Challenges and Solutions:

- Assembly and Testing: Intricate processes require advanced equipment for high-quality products.

- Thermal Management: Denser components necessitate effective heat dissipation techniques.

- High-Speed Signal Transmission: Advanced technologies ensure stable and reliable signals.

- Electromagnetic Compatibility: Shielding and grounding techniques mitigate interference for reliable operation.

In conclusion, 12-layer rigid-flex PCBs offer advanced technology with superior electrical and mechanical properties, making them ideal for high-performance electronic devices requiring reliability, integration, and flexibility.