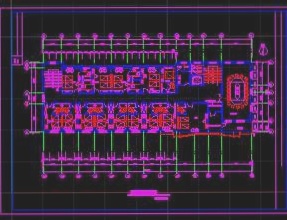

Common Mistakes in PCB Design to Avoid

-

Overlap of Pads

1. Overlapping pads can lead to drill bit breakage and hole damage during manufacturing.

2. Misinterpretation can occur when different types of holes overlap, resulting in scrap.

-

Abuse of Layers

1. Unnecessary connections on graphic layers can cause confusion, especially in designs with multiple circuit layers.

2. Proper layer mapping is crucial to avoid data transfer errors and maintain design clarity.

3. Deviating from conventional layer setups can lead to inconvenience and errors.

-

Random Placement of Characters

1. Character placement over pads can hinder testing and soldering processes.

2. Designing characters of incorrect sizes can affect screen printing and readability.

-

Single-Sided Pad Aperture

1. Design single-sided pads with a zero diameter to avoid drill coordinate issues.

2. Use special markings for single-sided pads with drilled holes.

-

Drawing Pads with Filled Blocks

Using filled blocks for pads may pass design checks but can complicate processing and solder mask data generation.

-

Electrical Stratum Complexity

Designing power supplies as flower pads can lead to ground plane issues and isolated connections.

Draw isolation lines carefully to prevent short circuits.

-

Unclear Processing Levels

Specify front and back for single-panel designs to avoid soldering difficulties.

Clearly explain the processing order for multi-layer boards.

-

Excessive Padding Blocks

Excessive padding blocks can result in incomplete light drawing data and complicate data processing.

-

Surface Mount Device Pad Length

Short pad lengths in surface mount devices can impact test pin installation.

-

Small Spacing of Large-Area Grids

Ensure grid line edges within large areas are at least 0.3mm apart to prevent printing issues.

-

Proximity of Copper Foil to Outer Frame

Keep large copper foil areas at least 0.2mm away from the outer frame to prevent warping.

-

Uneven Graphic Design

Uneven plating layers can impact the overall quality of the PCB.

-

Using Grid Lines for Large Copper Areas

Utilize grid lines to prevent PCB board blistering in large copper areas.