When a product designed by a PCB designer goes into production, it almost always encounters some problems. These problems are usually related to the production process and yield, or problems in the PCB assembly, resulting in product scrap or extensive rework. When the above situation occurs, the product needs to go back to the design stage to make necessary design revisions so that it can meet the predetermined production process.

PCB assembly: Introduction 2024

Printed circuit board assembly (PCB) involves firmly attaching electronic components to a printed circuit board using tin-lead solder (in a wave soldering machine or applied as a paste and then spread in a low-temperature oven) or epoxy resin (processed in a low-temperature oven).

The PCB type (single-sided, double-sided, multi-layer, or flexible) determines the density of the components that can be attached to it. The choice of PCB mounting method is driven by technology and reliability.

The main methods include full surface mounting technology (SMT), mixed technology (includes SMT technology and through-hole technology (PTH)), and technology for mounting components on the bottom side of the board.

Phases to Prepare Product Model

After designers submit bills of materials (BOMs), Gerber files, component location tables, drawings, netlists, and other data formats separately, assembly, test, and production engineers go through many steps to re-edit and model the product model before they can start the new product introduction (NPI) of the process segment.

A typical example is that a BOM and a complete set of assembly drawings (such as mechanical drawings of the assembled panels, the drawings to show the configuration data of the panel information, and the necessary dimensions for all panel definitions) are usually sent to the manufacturer.

These traditional drawings and data contain the product specifications and requirements required by the manufacturer, which are necessary information to produce the correct product.

Move DFM verification forward in the design phase

The PCB manufacturer recreates the drawings using the CAM system and sends the new drawings to the designer for confirmation.

Before designers can confirm that the drawings can be used for PCB manufacturing, it is often necessary to repeatedly modify the design of the PCB board, especially when there are design errors in the drawings.

This process is time-consuming and inefficient.

A better way to solve the above problems is to use a lean NPI process that runs through design and manufacturing. A lean NPI approach begins with the design organization conducting DFM analysis and providing feedback for optimization.

It includes building a manufacturing-level product model, which includes designing and validating the assembled board. The lean NPI process can automatically generate process data for manufacturing, assembly, and testing based on the mastered manufactured product model.

DFM Validation workflow

The lean NPI workflow consists of two phases, “Product” and “Process”. The product stage mainly solves production-related problems, and the process stage mainly solves the problem of how to produce. The ODB++ product model can realize the effective delivery and communication of these two stages.

ODB++ is an open intelligent single data structure that enables PCB design input for manufacturing, assembly, and testing. High-quality ODB++ product models can replace multiple traditional data files and drawings, thereby realizing automatic transfer and handover between products and processes.

Now, for all new PCB-based products, the design stage can be easily and efficiently linked to the process stage.

The design stage involves the function of the product, the physical model of the product, and the appearance of the finished product (system structure, principle circuit design, PCB design), and the process stage includes the manufacturing method and the process required to manufacture qualified products.

The Design Stage of PCB Assembly

PCB electronic products refer to the selection of capable electronic processing companies to help produce products in order to focus on the research and development and market development of new products.

The manufacturing process of PCBA electronic products mainly includes material procurement, SMT chip processing, DIP plug-in processing, PCBA testing, finished product assembly, and logistics distribution. The PCBA electronic manufacturing process is as follows:

Confirm cooperation and sign the contract

After the negotiation between the two parties, they signed a cooperation contract.

Customer orders and provides processing information

The customer starts placing the order and provides the bill of materials, PCB files, Gerber files, diagrams, and PCBA test plans for the product handling.

Purchase Parts

Electronic processing plants purchase component materials, PCB boards, stencils, and fixtures according to customers’ orders.

Material arrival, inspection, and processing

Material arrives; incoming material is inspected and processed and then delivered to PMC for planned production.

SMT chip processing, DIP plug-in processing

Materials are produced online, through solder paste printing, patch, reflow soldering, AOI inspection, DIP plug-in, wave soldering, and other processing links to complete PCB processing and soldering, and each step of processing will have a quality inspection.

PCBA testing

The electronic processing factory conducts testing according to its own testing process, combined with the test plan provided by the customer, to repair the defective products found.

Packaging and Shipping

After all the products are produced, they are packaged and shipped according to customer needs. PCBA electronic product processing is a relatively complex process. In the production process, every employee needs to work together and strictly follow the production process to control the quality, meet the customer’s quality requirements, and provide the perfect product.

Why DFM is important in PCB assembly?

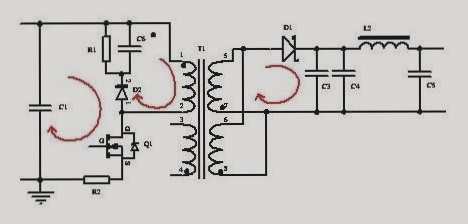

Typically, today’s electronics and computer assembly plants use mixed technology, where some components are surface-mounted and other connections and components are soldered using through-hole or solder flow techniques.

The following is a description of a “typical” mixed surface mount process including adhesive bonding, wave soldering, and flow soldering.

Mixed technology can sometimes flow solder surface mount components (SMCs) on the top side of a double-sided board, and wave solder SMCs on the bottom side. This method is especially useful when you need to use surface mount technology and through-hole technology on the same board, which is common in today’s electronics industry.

The first step is to attach the SMCs to the top side of the board using the drip solder technique. The next step is to insert the components through the through holes.

The board is then flipped over and the SMCs are attached to the underside of the board with adhesive. The final step is wave soldering the components in the through holes and on the underside of the board.

The production of printed circuit boards using mixed technology includes the following main stages:

- preliminary and additional cleaning;

- application of solder paste and adhesive (screen printing and placement (SMT and PTH));

- introduction of components;

- Adhesive handling and solder runoff

- fluxing (RTN)

- wave soldering (RTN);

- visual inspection and correction of defects

- tests

- repair and replacement of defective components

- auxiliary operations – cleaning the stencil.

The environmental, health, and safety issues for each process step are briefly discussed below.

Pre and post cleaning

Commercially printed circuit boards (PWBs) are typically purchased from a PWB supplier where they are pre-cleaned with a deionized (DI) aqueous solution to remove surface contaminants.

Before there was concern about the state of the ozone layer, chlorofluorocarbon (CFC), a substance that depletes the ozone layer, was used in the final or even pretreatment stage by electronics manufacturers.

At the final stage of PCB assembly, CFC “steam degreasing” was typically performed to remove wave solder and flux residues. The problems of maintaining the ozone layer and severe limitations in the production of CFCs have led to technological changes that allow PCB assembly to eliminate the cleaning process or use only deionized water cleaning.

Applying Solder Paste and Adhesive and Inserting Components

Applying tin-lead solder paste to the surface of a PWB board allows surface mount components to be attached to a PWB board, which is the basis of SMT technology.

The solder material acts as a mechanical binder for electrical and thermal conductivity, as well as a protective surface coating and improves solderability. The solder paste consists of approximately 70-90% non-volatile matter:

Tin-lead solder;

- a mixture of modified resins (resin acids or slightly activated resins)

- activators (in the case of products that do not require cleaning, mixtures of amine halides and acids, or simply carboxylic acids)

- Solvents (volatile matter) make up the remainder of the materials (usually a proprietary mixture of alcohol and glycol ether).

The solder paste is applied through a stencil, which is an exact copy of the surface pattern formed on the surface of the board (PWB). The solder paste is forced through the holes in the stencil onto the pads on the PWB using a special knife that slowly moves the stencil.

The concentration of lead in the solder and the stickiness of the dried paste necessitate the use of protective gloves, thorough cleaning of work surfaces, removing contaminated cleaning materials; and maintaining strict personal hygiene.

Lead concentrations in the air are usually below the detection limit, and blood lead readings are within the normal range when good personal and indoor hygiene practices are followed.

Applying Adhesives in PCB Assembly

Applying the adhesive involves automatically pouring small amounts of epoxy (typically a bisphenol A-epichlorohydrin blend) onto the surface of the PWB and “picking and placing” the component and injecting it through the epoxy onto the PWB.

In this case, the risk factor is mechanical devices for “grabbing and moving” components with a shuttle movement, presenting a risk of serious injury if not properly protected and locked out of the equipment.

Adhesive processing and solder runoff

Components attached by screen printing or adhesive application are moved by a fixed-height mechanical conveyor to the runoff furnace. In the furnace, the solder “separates” when the solder paste, heated to a temperature of 200 -, re-spreads. The components attached with the epoxy adhesive are also run through an oven that is connected to the previous drip oven and is typically operated at 130.

Solvent components, solder pastes, and epoxy resin are removed during furnace processing, but the tin-lead component does not volatilize. A web-type residue is formed in the outlet pipe of the runoff furnace. A metal strainer can be used to prevent this. PCBs can sometimes get caught in the conveyor system and overheat in the oven, causing bad odors.