Types of PCB Circuit Boards Based on Layers

- Single-sided PCB board: Wiring on one side only

- Double-sided PCB board: Wiring on both sides

- 4-layer PCB board

- 6-layer PCB board

- 8-layer PCB board

- Other multi-layer PCB circuit boards

Methods to Identify PCB Layers:

- Observe the “holes” on the PCB board. Double-sided and four-layer boards are usually transparent, while boards with 6 layers or more are not.

- Examine Gerber data, focusing on each layer like drilling, solder mask, impedance, circuit, and board outline layers. Software tools can help visualize the layer count.

- Use anti-reverse engineering software when PCB files are not available.

- Request PCB cross-sectional analysis reports from factories for precise layer identification.

Importance of PCBs:

- PCBs are essential for electronic devices.

- They facilitate component connections and signal transmission.

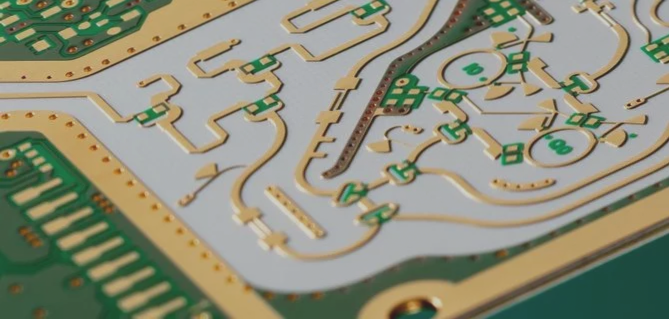

- Composed of glass fiber and copper foil, offering good conductivity and mechanical properties.

- Design considerations include circuit connections, layout, and heat dissipation.

- Optimal PCB layout reduces electromagnetic interference and signal delay.

- Quality PCB design enhances device reliability and stability.

- Strict quality control in manufacturing is vital for PCB production.

- Qualified PCBs enhance product performance and longevity.

- PCBs significantly impact electronic device quality and reliability.

Latest PCB Industry Trends:

Recent advancements in PCB technology focus on enhancing signal integrity, reducing power consumption, and improving thermal management. The integration of IoT devices has led to a surge in demand for flexible and high-density interconnect solutions. Additionally, eco-friendly materials and processes are gaining popularity in PCB manufacturing to promote sustainability and reduce environmental impact.

Future of PCB Design:

The future of PCB design lies in miniaturization, increased automation, and the adoption of advanced materials like flexible substrates and 3D printing. AI-driven design tools are revolutionizing the industry by optimizing layouts for performance and manufacturability. As electronics continue to evolve, PCBs will play a pivotal role in enabling innovative and efficient device designs.