The Anatomy of a PCB (Printed Circuit Board)

A PCB comprises two primary components: the substrate and the circuit layer. The substrate, typically crafted from engineering plastics, boasts exceptional thermal and electrical insulation properties, as well as resistance to bending. On the other hand, the circuit layer features copper foil, also known as copper cladding, covering the outer surfaces of the base layer.

At the heart of the PCB lies the circuit layer. Designers utilize specialized software to draft the circuit, following which a dedicated machine engraves the copper foil layer based on the design specifications. This process eliminates unwanted sections, culminating in a fully formed circuit. Simultaneously, components like chips, resistors, capacitors, and connectors are soldered or mounted onto the PCB, seamlessly integrating with the copper foil layer to complete the circuit assembly.

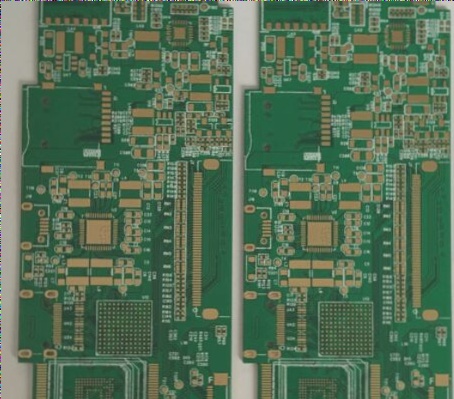

Single vs. Multi-Layer PCBs

Typically, a PCB consists of two layers positioned on the top and bottom surfaces of the substrate. However, in more intricate scenarios where a single layer cannot accommodate all necessary lines or control the circuit effectively, multi-layer PCBs come into play. These boards, comprising stacked single-layer PCBs, allow for the design of different circuits on separate layers to meet complex circuitry requirements.

Multi-layer PCB configurations vary, ranging from 2 layers to beyond 10 layers. To identify a multi-layer PCB, shine a light through the board and observe areas where copper is absent on the upper and lower surfaces. Translucent areas indicate the presence of internal layers, though accurately counting them can be challenging without expertise.

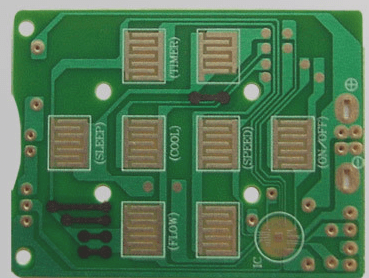

Color and Layer Considerations

While there is no standardized color for PCB boards, green remains the most prevalent due to its non-dazzling surface. Some manufacturers opt for different colors like purple, yellow, or black to enhance visual appeal on premium products. The number of layers in a PCB is determined by industry needs, with rigorous reliability testing conducted on all boards regardless of layer count.

Understanding the number of layers in a PCB may not be essential for most businesses making purchasing decisions, as reliability testing ensures even lower-layer boards meet performance standards.