Optimizing High-Frequency PCB Design: Best Practices

1. Keep Wire Leads Short:

- Shorter wire leads between pins reduce signal radiation intensity, especially for high-frequency signals like signal clocks, crystal oscillators, and DDR data lines.

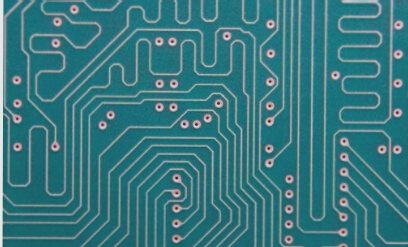

2. Minimize Bends:

- Limit bends in high-frequency circuit board wiring to maintain structural integrity and reduce external emissions and signal interference.

3. Separate Ground Wires:

- Segregate ground wires for high-frequency digital and analog signals to prevent voltage differences and interference. Use isolation techniques like high-frequency choke magnetic beads.

4. Avoid Wiring Loops:

- Avoid creating loops in high-frequency signal traces and minimize loop area when unavoidable.

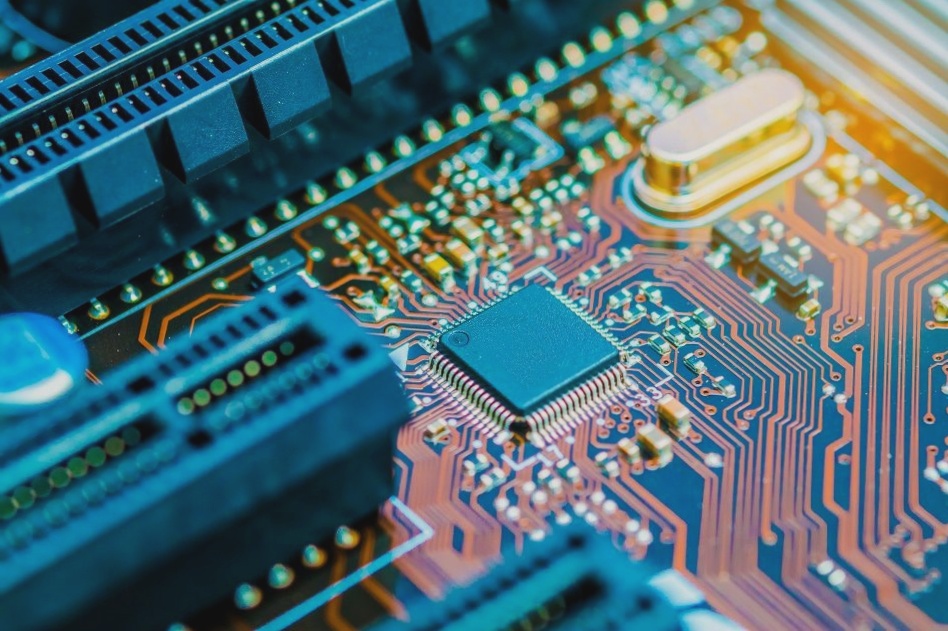

5. Reduce Vias:

- Minimize the use of vias to decrease distributed capacitance and improve signal speed, reducing the risk of data errors.

6. Utilize Decoupling Capacitors:

- Integrate high-frequency decoupling capacitors at power supply pins of integrated circuits to mitigate interference from high-frequency harmonics.

New Insights:

Recent studies suggest that implementing advanced simulation tools can further optimize high-frequency PCB design by predicting signal behavior accurately before physical implementation. By simulating signal integrity, power integrity, and electromagnetic interference, engineers can preemptively address potential issues, leading to enhanced performance and reliability.