Advanced Techniques in PCB Fabrication for High-Frequency Multi-Layer Boards

- Proper Handling of VIA Holes under BGA Components

- Double-Sided Solder Mask with Defined Points

- Preventing Damage to Circuit Lines

Plugging Services Offered by WellCircuits Limited

WellCircuits Limited provides two specialized plugging services tailored to customer needs:

- Resin Plugging: Utilizes solvent-free ink to address difficult filling issues and reduce the risk of ink cracking during heating.

- Electroplating Filling: Controls copper deposition rate using additives, beneficial for continuous multi-layer laminated hole boards or high-current PCB designs.

Key Considerations During PCB Assembly

- Avoiding Flux Residue Blockage in VIAs

- Preventing Solder Beads Popping Out During Wave Soldering

- Avoiding Solder Bridges Caused by Surface Tin Flow

- Ensuring PCB Board Qualification Through Testing

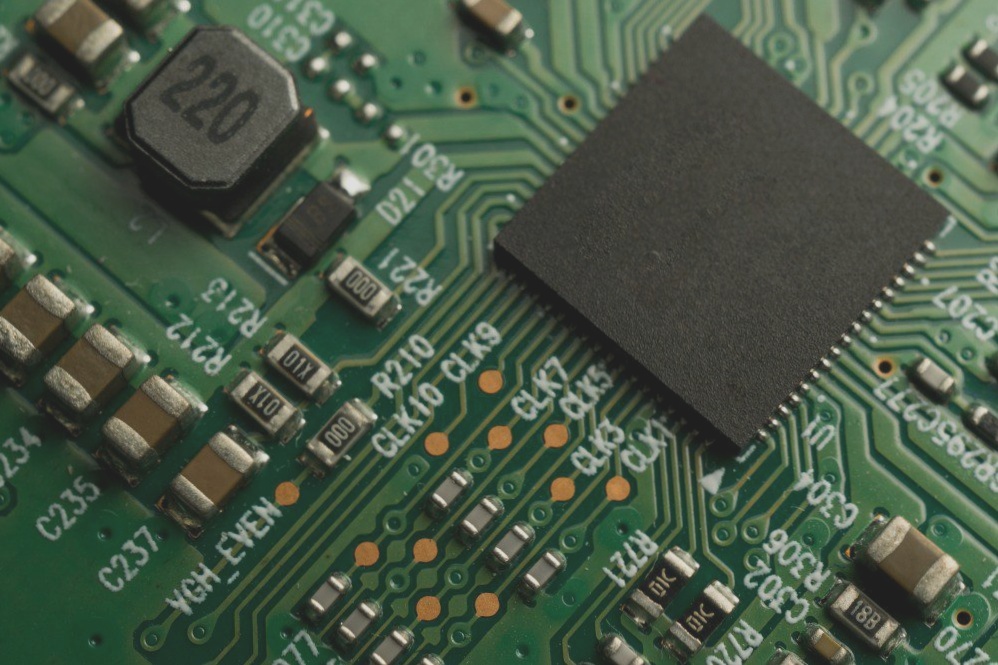

Understanding PCB Solder Mask Openings

The PCB solder mask layer, coated with protective ink, plays a crucial role in PCB fabrication. Solder mask openings expose copper pads for soldering, facilitating signal measurement and preventing leakage.

Types of Solder Mask Inks

- Liquid Photosensitive Ink: Ideal for small batch, high-precision PCB production with personalized designs.

- UV Solder Mask Ink: Features rapid fixation, heat resistance, and strong adhesion for single-sided and double-sided circuit boards.