Challenges and Solutions for PCB Design in the 5G Era

The advent of 5G technology presents unique challenges in PCB design and manufacturing, especially for high-frequency applications. Meeting the exacting technical demands of 5G requires precise patterns and the use of complex materials. Consequently, the industry needs to adopt advanced imaging, inspection, and measurement technologies to produce the high-performance PCBs essential for 5G infrastructure and devices.

Increasing Need for Specialized PCB Types

The expansion of 5G infrastructure, encompassing cellular base stations, data centers, high-performance computing systems, and AI applications, is fueling the demand for specialized PCBs like fine-line IC carrier boards and high-level digital (HLC) multi-layer boards (MLBs). Moreover, the rising requirement for 5G antennas, camera modules, and display drivers is driving the need for high-density interconnect (HDI) boards, including multi-layer HDI designs. These evolving demands are pushing traditional PCB technologies to their limits, necessitating more sophisticated design and manufacturing approaches.

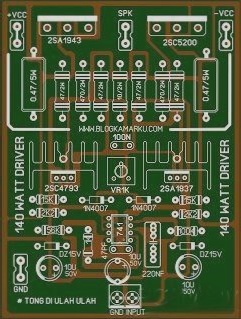

Advanced Imaging Technologies in PCB Manufacturing

To address the manufacturing challenges posed by 5G PCBs, the integration of new imaging and inspection technologies is crucial. These cutting-edge techniques are vital for producing the high-precision, intricate PCBs demanded by the 5G landscape. Key technologies include Direct Imaging (DI) for high-resolution imaging of fine patterns, Automatic Optical Inspection (AOI) systems for real-time quality control, and Automatic Optical Shaping and Repair systems for enhancing PCB production by detecting and correcting imperfections.

It’s important to recognize that the manufacturing requirements for PCBs differ based on their application in either 5G infrastructure or end-user devices. Infrastructure-focused PCBs typically necessitate robust, multi-layer boards, while device-centric PCBs require specialized HDI designs and finer interconnects.

Adapting to the Evolution of 5G Technology

As 5G technology advances, the demand for highly specialized PCBs will continue to grow. To address these challenges effectively, the PCB industry must embrace innovative technologies that enable more precise imaging, inspection, and repair processes. This adaptation is crucial for ensuring the production of high-quality, high-performance PCBs essential for the successful deployment of 5G infrastructure and devices.

5G Infrastructure and the Significance of DI Technology in PCB Manufacturing

Within the realm of 5G infrastructure, Direct Imaging (DI) technology plays a pivotal role in achieving the stringent impedance control required for high-frequency 5G signals, including millimeter waves. DI technology ensures precise layer alignment, particularly on large panels, crucial for advanced digital multi-layer boards (MLB) production. Capable of supporting large-sized panels and warped substrates, DI technology maintains the necessary resolution and accuracy for 5G applications. High-capacity solder mask (SM) DI technology further enhances capabilities to meet the specific demands of 5G by offering flexibility for large-scale and intricate PCB designs.

Automated Optical Inspection (AOI) in PCB Manufacturing

Automated Optical Inspection (AOI) stands as a critical component of PCB manufacturing for 5G infrastructure. AOI systems must provide highly accurate inspection and measurement with minimal manual intervention. Specifically, AOI should detect fine lines as small as 5 μm, a typical requirement for IC carrier boards utilized in High-Performance Computing (HPC) and data server applications within 5G networks.

The Latest Innovations in 5G PCB Manufacturing

When it comes to 5G devices, Direct Imaging (DI) technology combined with Automated Optical Inspection (AOI) now provides high-quality imaging for precise conductor geometries and superior scaling. These capabilities are crucial for advanced semi-additive process (mSAP) or carrier-like PCB (SLP) manufacturing, which demand intricate and highly accurate designs. Integrating AOI with DI technology can boost production capacity and yield, ensuring efficiency and quality in high-volume PCB production.

Enhancing Flexible Printed Circuits (FPC) with Roll-to-Roll DI Systems

As 5G technology drives the demand for smaller and lighter electronic products, Flexible Printed Circuits (FPCs) play a vital role. The shift to flexible materials poses challenges for PCB manufacturers, requiring them to maintain material integrity while minimizing processing damage. Roll-to-roll DI systems offer a solution by enabling FPC manufacturers to process roll-based flexible materials with minimal deformation and high-quality standards.

Improved Inspection with 2D Laser and Linewidth Measurement

Quality assurance for 5G PCBs often involves integrated AOI systems with 2D laser blind hole measurement. This technology precisely measures blind holes’ dimensions and positions, ensuring correct alignment and impedance control on advanced 5G boards. Additionally, AOI systems with 2D linewidth measurement capabilities are essential for accurate top and bottom layer measurements, crucial for impedance control in high-frequency signals like those used in millimeter wave antennas.

Addressing 5G PCB Inspection Challenges

Inspecting 5G PCBs presents challenges like examining low-contrast material layers, transparent flexible circuits, and laser blind holes. The inspection process must deliver fast and accurate measurements to maintain strict impedance control while reducing system ownership costs. Innovative techniques, such as high-contrast imaging for low-contrast materials, are emerging to improve defect detection without generating false alarms.

Advancements in Optical Shaping and Repair Technology

One notable innovation in 5G PCB manufacturing is automatic optical shaping and repair technology. This process allows manufacturers to swiftly and precisely repair open and short circuits in HDI PCBs, mSAP boards, and IC carrier boards during production. Optical repair technology integration reduces manual intervention, saving time and minimizing scrap material. By enhancing the repair process and overall quality, optical shaping technology boosts production yield, meeting the demands of 5G PCB mass production.

Impact of 5G on PCB and IC Carrier Board Design

The rise of 5G technology has reshaped PCB and IC carrier board design and manufacturing. The quest for compact, high-performing devices necessitates precision in design and production processes. Manufacturers are adopting advanced technologies like DI, AOI, and optical shaping to ensure accurate mass production meeting 5G application standards. Continuous advancements in PCB and IC carrier board design promise increased reliability, efficiency, and scalability for 5G infrastructure demands.

5G technology’s evolution has driven innovation in PCB manufacturing, emphasizing precision, automation, and flexibility. Leveraging cutting-edge technologies like DI, AOI, and optical repair enables manufacturers to meet 5G’s stringent demands, enhancing production yield and quality.