Purchasing PCBA: Key Considerations for Quality Assurance

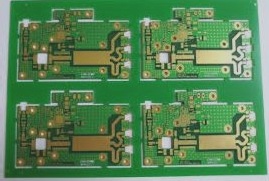

When purchasing Printed Circuit Board Assembly (PCBA), it is essential to evaluate various factors to ensure quality assurance and maximize benefits. WellCircuits Limited, a professional enterprise specializing in electronic processing, offers advanced technology, management, and service levels for reliable PCBA production.

Factors to Consider:

- Assess the supplier’s technology, management, and service level.

- Ensure professional ultrasonic cleaning of the PCBA board surface.

- Pay extra attention to the welding quality of PCBA components.

- Conduct ageing tests to evaluate stability and reliability.

- Adhere strictly to operational specifications during the assembly process.

- Evaluate the supplier’s after-sales service capabilities.

- Opt for fair pricing to ensure reasonable profits for PCBA manufacturers.

Additional Insights:

The cleanliness of the PCBA board surface is crucial to prevent risks to electronic product usage. Additionally, the reliability of PCBA component welding directly impacts the product’s lifespan. Genuine components and strict testing are vital to avoid product failure.

PCBA Ageing Test Performance Report

Thoroughly analyzing ageing test performance is crucial when procuring bulk PCBA to ensure stability and reliability under extreme conditions. Suppliers should provide comprehensive ageing test performance reports to prevent defects and losses.

PCBA Assembly Process Management

Adhering to standardized assembly processes is critical to prevent damage to well-tested PCBA boards during the assembly process.

After-sales Service Capabilities

Assessing a supplier’s after-sales service capacity is essential to address and resolve issues promptly, ensuring a smooth procurement process.

Ensuring Reasonable Profits

Prioritize fair pricing to guarantee reasonable profits for PCBA manufacturers, reflecting strong service capabilities and quality standards.