I. Original manuscript (using film or sulphate paper)

The circuit diagram is designed and printed onto transparent film or translucent sulphate paper using a laser (inkjet) printer.

Matters needing attention:

1. The exposed part will be removed by the developer to reveal the copper surface. Ensure mirror printing is selected during the printing process. The circuit diagram printing ink (toner) surface must be closely connected with the green photosensitive film surface to achieve the highest resolution. (Drawing software typically includes the Mirror printing function).

2. If there are holes in the circuit, they should be repaired with an oily black pen.

3. The surface of the draft should be kept clean and free of dirt.

Second, the exposure.

First, tear off the protective film, and place the printing surface of the printed circuit diagram (toner surface/ink surface) onto the photosensitive film surface. Press the manuscript and the photosensitive plate together with glass; the tighter the resolution, the better.

A: Standard exposure time with a 20W daylight lamp:

– Transparent draft: 8-10 minutes

– Translucent: 13-15 minutes

B: Using sunlight:

– Strong daylight:

– Transparent draft: 1-2 minutes

– Translucent draft: 2-4 minutes

– Low sunlight:

– Transparent draft: 2-3 minutes

– Translucent draft: 4-5 minutes

Double panel exposure method:

1. Preferred method of hole positioning for double panel exposure:

– Use both sides of the original manuscript, fix it with adhesive paper, and align it well with the photosensitive plate without removing the protective film. Diagonally drill positioning holes with a small 1.0mm drill. Finally, align the positions using two small bits, fix them with adhesive paper, and then expose them separately.

2. Another method:

– The manuscript is double-faced, fixed on both sides with adhesive paper, and then inserted into the photosensitive plate. Double-sided adhesive paper is used to paste and fix the original manuscript with the photosensitive plate.

Fine lines less than 0.5mm require a double-sided exposure machine.

Third, Imaging

1. Prepare imaging agent: Use water (1:80) for the imaging agent, meaning 1 pack of 20g imaging agent mixed with 1600 ml of water can develop approximately 8 10x15cm single photosensitive plates. (Mineral water bottles typically indicate capacity; for reference, use a plastic basin instead of a metal one for imaging.)

2. Development: Place the photosensitive plate facing up (double panel must be suspended).

Gently shake the container or plate every few seconds until the copper foil is clear and no longer appears greenish. Wait a few seconds to ensure the image is fully developed.

* The standard development time is approximately 1-2 minutes. Development can occur under general light, but it’s crucial to monitor the progress continuously; never rely solely on the development time.

3. Rinse with water.

4. Drying and Inspection: To safeguard the film surface from damage, it’s preferable to perform this step. Use a hairdryer for drying, remove short circuits with a knife, and repair broken wires with an oily pen.

Points to Consider:

1. Use a mineral water bottle to prepare the development liquid in proportion first. While it can be poured out for use at any time, the used development liquid cannot be poured back into the bottle.

2. Thicker development fluid leads to faster development, but excessive speed can cause overdevelopment (blurring and shrinking of lines in all directions). Conversely, overly thin fluid results in slow development and may cause incomplete etching.

3. Do not reuse the used development fluid. After 24 hours, the used development fluid will gradually decompose without causing environmental pollution.

4. Take strict precautions to prevent scratching the film surface.

Four, Etching

Preparation of Ferric Chloride Etching Solution: Mix 250g of ferric chloride with 1500ml – 2000ml of water. Preferably melt with hot water to facilitate etching of fine lines.

A. Plastic Basin: Etching time is about 5 ~ 15 minutes. Gently shake the plastic basin during etching.

B. Etching Machine: With a new solution, etching time takes about 1.5 ~ 3 minutes. Thin lines less than 0.5mm must be etched.

C. Rinse.

D. Dry.

Points to Consider:

1. Take care not to damage the film surface.

2. Dip the plate into the etching solution for about 2 seconds, then inspect to check for successful development. To remedy underdevelopment, if copper foil in non-circuit areas turns pink, rinse the product with water before redeveloping in the development solution (reduce development time accordingly).

3. Photosensitive film can be directly welded without removal. If necessary to remove, available solvents include alcohol and acetone.

4. The thicker the etching solution, the slower the process.

The figure below illustrates the schematic board fabrication.

Fabricating the plate is straightforward. All above-mentioned times serve as references only; actual testing is key. Conduct tests with a few small plates to gauge proficiency; typically, one or two tests suffice. After mastering, your produced circuit board quality will match or surpass that of professional PCB manufacturers.

———————————————————————————————————-

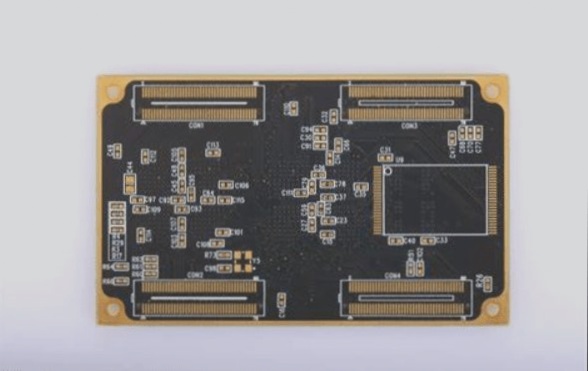

Photosensitive plates cater to electronic enthusiasts, professional students, and engineers in the electronic research, development, and testing industries. These plates offer convenient production without requiring professional equipment. (Refer to the instructions for production methods.)

Standard size: 100mm × 150mm single-sided electric board. Features include uniform photosensitive film, quick exposure, easy development result judgment, high success rate, user-friendliness, low cost, and strong confidentiality. Priced at 10 yuan per tablet, including one package of developer for a total of 10 yuan. (One developer pack allows imaging of five standard 100mm × 150mm plates!) Discounts available for bulk purchases.

Photosensitive circuit boards, also known as photosensitive PCBs, involve evenly coating a circuit board with photosensitive film. Where light strikes, the film dissolves via the developer, leaving the copper skin intact on the circuit board, impervious to ferric chloride corrosion, and preserved as a line!

High-precision base circuit boards can be corroded with special corrosives at 0.2mm/0.1mm (equivalent to three lines within 1mm). Even under amateur conditions, lines of 0.3mm/0.2mm (equivalent to two lines within 1mm) can be corroded. However, achieving a line width and spacing of 0.6mm/0.4mm (i.e., walking a line within 1mm) manually is challenging.

In reality, precision is very high, comparable