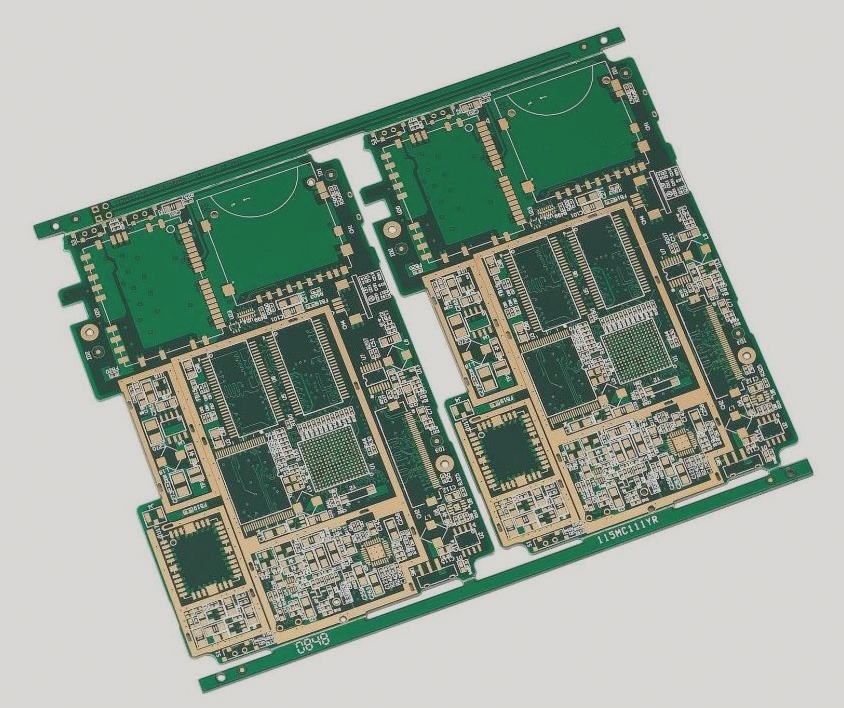

Key Variations between Wave Soldering and Reflow Soldering

When it comes to PCB manufacturing, understanding the disparities between wave soldering and reflow soldering is crucial. These two soldering techniques differ significantly in their processes and outcomes. Let’s delve into the variances:

- Wave Soldering:

- Utilizes a wave crest of melted solder to solder components.

- More intricate compared to reflow soldering.

- Requires precise monitoring of temperature and time to avoid defects.

- Efficient and cost-effective, ideal for bulk PCB soldering.

- Suitable for through-hole component soldering.

- Reflow Soldering:

- Uses reflow via hot air for soldering.

- Less complex than wave soldering.

- Offers flexibility in design without stringent environmental controls.

- Slower and more expensive, suitable for small PCB batches.

- Does not require considerations like wave soldering for efficient results.

Choosing the right soldering technique depends on factors like the scale of production, component types, and cost considerations. Understanding these differences will help you make an informed decision for your PCB manufacturing needs.

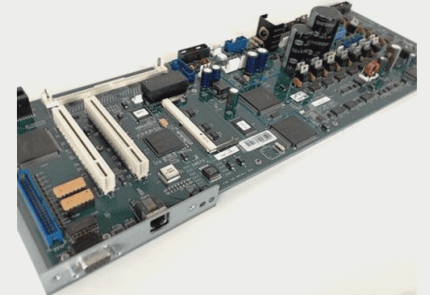

Surface Mount Devices Technique for PCB

When working with surface mount devices on your PCB, consider utilizing a specific technique for efficient results.

Choosing the Right Soldering Method

When it comes to soldering processes for printed circuit boards, both reflow and wave soldering methods have their advantages and disadvantages. The selection of the appropriate method depends on the PCB design and the specific requirements set by the company.

If you are new to the soldering process, it is advisable to seek expert assistance before proceeding. Consulting with experienced professionals in PCB manufacturing and design can help you determine the most suitable soldering technique for your needs.

Expert Guidance for Optimal Results

By collaborating with a reputable manufacturer, you can gain insights into the key differences between reflow and wave soldering techniques. Their expertise can streamline the decision-making process and prevent potential errors that may lead to wasted time and resources.

Prioritize technical and operational considerations when selecting a soldering method to avoid unnecessary costs and ensure successful outcomes for your PCB projects.