Are you looking for a supplier for LED circuit boards? Let us see if we can assist you. In this article, we will highlight the benefits of LEDPCBs and their applications. We will also cover material selection and production considerations. The manufacturing process of LED boards can be complex, with many factors to take into account. Let’s dive in.

What is LEDPCB?

Compared to standard lighting products, light-emitting diodes offer several advantages. However, the light output of a single LED is relatively low. To increase light output, multiple LEDs are connected to the PCB or LED circuit board. When current passes through the LED, it emits light. However, as the current increases, the heat generated by the LED also increases. This is problematic because high temperatures can reduce the LED’s light output. Therefore, manufacturers use the circuit board layer to dissipate heat away from the LED.

LEDPCB Material

When selecting an LEDPCB substrate, it is essential to carefully consider the thermal properties of the material. Weight, size, and cost are also important factors. Substrate material options include:

– FR4 PCB raw materials

– CEM-1 PCB raw materials

– CEM-3 PCB raw materials

1. The IC layer will act as a crucial link between the IC and the heat sink. Unlike FR4, PCB materials such as copper and aluminum offer different thermal properties.

2. Copper core PCB materials.

3. Ceramic-based PCB materials.

4. Each material has its own advantages and disadvantages. For example, metals and ceramics generally offer superior thermal performance compared to laminates. The CEM-1 board is cost-effective but more fragile compared to FR4 and CEM-3 boards.

5. Ceramic-based PCBs often use materials like alumina. Although there are other materials with superior thermal properties, they are generally more expensive. Similarly, metal core PCBs, including aluminum and copper, present a trade-off between cost and performance.

6. Advantages of LEDPCBs in the LED lighting industry:

7. Compared to traditional lighting, LEDPCBs offer several benefits, such as:

8. Lower power consumption

9. Longer service life

10. Greater efficiency

11. Compact design

12. Mercury-free

13. Customizable shapes and colors allow for diverse lighting effects.

14. Applications of LEDPCBs:

15. The recognition of LED circuit boards’ benefits is increasing, leading to a rise in their applications, such as in:

16. Automotive

17. Medical devices

18. Computers

19. Telecommunications

20. Military

21. Traffic signals and lighting

22. Indoor agricultural lighting

23. Market demands, including advancements in LED technology, green energy trends, and cost reductions, are driving growth. Consequently, the compound annual growth rate (CAGR) of the LED circuit board lighting market is projected to be 14.25% from 2021 to 2026.

24. LEDs can be either surface-mounted or lead-packaged. Surface-mount devices (SMDs) are preferred for multi-device applications due to their small size and thin profile.

25. SMD LED assembly requires advanced manufacturing skills. Manufacturers must accurately place LED circuits and components on small PCBs, often using pick-and-place equipment.

26. The process includes printing solder paste onto PCB pads, placing the SMD LED on the pad, and heating the assembly to form solder joints.

27. Accurate placement of LED components is critical, as is ensuring the solder paste is level and within the specified thickness range. Proper heat control is essential to prevent damage to the LED devices.

28. Aluminum LED circuit boards:

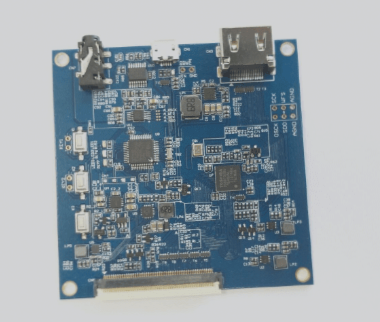

29. The construction of printed wiring boards involves layering four materials: screen printing, solder mask, copper layer, and substrate.

30. SMD LEDs are connected to the PCB surface. Due to the concentration of SMD devices in a small area, heat dissipation becomes a concern. To manage this, LEDPCBs use a metal substrate to transfer heat away from the LEDs, with a dielectric material insulating the substrate from the circuit.

31. When selecting the best layout, options such as aluminum are common choices for metal substrates due to their durability and resistance to pressure. Although aluminum’s thermal conductivity is lower than that of copper, it is more affordable.

32. Choosing an LEDPCB manufacturer:

33. It is crucial to select a manufacturer with relevant experience, as LEDPCB production is complex and requires expertise in surface-mount technology and specialized equipment.

34. Ensure the manufacturer can meet your production volume and delivery requirements, with costs aligned with your budget and specifications.

35. Customer/supplier partnership:

36. The supplier should be responsive and work collaboratively to improve your LEDPCB products and help reduce costs.

37. Quality manufacturer:

38. Consider factors such as the type of LED and ensure the manufacturer consistently delivers high-quality products.

39. In conclusion:

40. The advantages of LED lighting are clear, and future applications may increasingly favor LEDPCBs. When selecting a PCB manufacturer for your LED circuit boards, choose carefully to ensure the best fit for your application.

41. Effective thermal management is essential, so select appropriate circuit board technology. Aluminum LED circuit boards offer numerous advantages and are a widely adopted solution.

42. Look for manufacturers who can address the challenges of circuit board production and deliver reliable products on time and at a reasonable cost.

What is LEDPCB?

Compared to standard lighting products, light-emitting diodes offer several advantages. However, the light output of a single LED is relatively low. To increase light output, multiple LEDs are connected to the PCB or LED circuit board. When current passes through the LED, it emits light. However, as the current increases, the heat generated by the LED also increases. This is problematic because high temperatures can reduce the LED’s light output. Therefore, manufacturers use the circuit board layer to dissipate heat away from the LED.

LEDPCB Material

When selecting an LEDPCB substrate, it is essential to carefully consider the thermal properties of the material. Weight, size, and cost are also important factors. Substrate material options include:

– FR4 PCB raw materials

– CEM-1 PCB raw materials

– CEM-3 PCB raw materials

1. The IC layer will act as a crucial link between the IC and the heat sink. Unlike FR4, PCB materials such as copper and aluminum offer different thermal properties.

2. Copper core PCB materials.

3. Ceramic-based PCB materials.

4. Each material has its own advantages and disadvantages. For example, metals and ceramics generally offer superior thermal performance compared to laminates. The CEM-1 board is cost-effective but more fragile compared to FR4 and CEM-3 boards.

5. Ceramic-based PCBs often use materials like alumina. Although there are other materials with superior thermal properties, they are generally more expensive. Similarly, metal core PCBs, including aluminum and copper, present a trade-off between cost and performance.

6. Advantages of LEDPCBs in the LED lighting industry:

7. Compared to traditional lighting, LEDPCBs offer several benefits, such as:

8. Lower power consumption

9. Longer service life

10. Greater efficiency

11. Compact design

12. Mercury-free

13. Customizable shapes and colors allow for diverse lighting effects.

14. Applications of LEDPCBs:

15. The recognition of LED circuit boards’ benefits is increasing, leading to a rise in their applications, such as in:

16. Automotive

17. Medical devices

18. Computers

19. Telecommunications

20. Military

21. Traffic signals and lighting

22. Indoor agricultural lighting

23. Market demands, including advancements in LED technology, green energy trends, and cost reductions, are driving growth. Consequently, the compound annual growth rate (CAGR) of the LED circuit board lighting market is projected to be 14.25% from 2021 to 2026.

24. LEDs can be either surface-mounted or lead-packaged. Surface-mount devices (SMDs) are preferred for multi-device applications due to their small size and thin profile.

25. SMD LED assembly requires advanced manufacturing skills. Manufacturers must accurately place LED circuits and components on small PCBs, often using pick-and-place equipment.

26. The process includes printing solder paste onto PCB pads, placing the SMD LED on the pad, and heating the assembly to form solder joints.

27. Accurate placement of LED components is critical, as is ensuring the solder paste is level and within the specified thickness range. Proper heat control is essential to prevent damage to the LED devices.

28. Aluminum LED circuit boards:

29. The construction of printed wiring boards involves layering four materials: screen printing, solder mask, copper layer, and substrate.

30. SMD LEDs are connected to the PCB surface. Due to the concentration of SMD devices in a small area, heat dissipation becomes a concern. To manage this, LEDPCBs use a metal substrate to transfer heat away from the LEDs, with a dielectric material insulating the substrate from the circuit.

31. When selecting the best layout, options such as aluminum are common choices for metal substrates due to their durability and resistance to pressure. Although aluminum’s thermal conductivity is lower than that of copper, it is more affordable.

32. Choosing an LEDPCB manufacturer:

33. It is crucial to select a manufacturer with relevant experience, as LEDPCB production is complex and requires expertise in surface-mount technology and specialized equipment.

34. Ensure the manufacturer can meet your production volume and delivery requirements, with costs aligned with your budget and specifications.

35. Customer/supplier partnership:

36. The supplier should be responsive and work collaboratively to improve your LEDPCB products and help reduce costs.

37. Quality manufacturer:

38. Consider factors such as the type of LED and ensure the manufacturer consistently delivers high-quality products.

39. In conclusion:

40. The advantages of LED lighting are clear, and future applications may increasingly favor LEDPCBs. When selecting a PCB manufacturer for your LED circuit boards, choose carefully to ensure the best fit for your application.

41. Effective thermal management is essential, so select appropriate circuit board technology. Aluminum LED circuit boards offer numerous advantages and are a widely adopted solution.

42. Look for manufacturers who can address the challenges of circuit board production and deliver reliable products on time and at a reasonable cost.