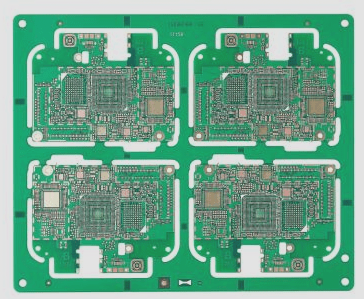

Component Placement Guidelines for Circuit Boards

- Positioning Decoupling Capacitors:

- Inductor Placement:

- Heat Considerations:

- Switching Regulator Components:

- AC Power Section:

When placing decoupling capacitors on a circuit board, it is essential to consider other component placement guidelines to ensure optimal performance.

Inductors should not be placed too closely together to avoid unwanted coupling. If inductors must be positioned near each other, they should be placed perpendicular to minimize mutual coupling. Ring or toroidal inductors are recommended for minimal stray magnetic fields.

When dealing with components that generate heat, such as power resistors, consider the impact on nearby components. Avoid placing thermistors used for temperature compensation near power resistors to prevent interference.

Group all components associated with an on-board switching regulator together on a designated section of the PCB. Keep these components away from areas handling small signals to prevent noise interference with sensitive circuitry.

When applying AC power directly to the PCB, cluster AC components in one part of the board. Include a physical barrier, such as a slot in the PCB, to separate the AC section from the rest of the circuit for safety and performance reasons.