Essential Automotive PCB Prototyping Tips

When working on automotive PCB prototyping, it is crucial to pay special attention to the following key aspects:

- Soldering Iron Usage: Always ensure the soldering iron is not energized and ground the soldering iron shell for safety. When dealing with MOS circuits, use a low-voltage circuit iron (6~8V) to enhance safety.

- Integrated Circuit Inspection and Repair: Before inspecting and repairing integrated circuits, understand their functions, internal circuits, key electrical parameters, and pin roles. When measuring DC voltage, use a multimeter with an internal resistance greater than 20KΩ/V to minimize errors.

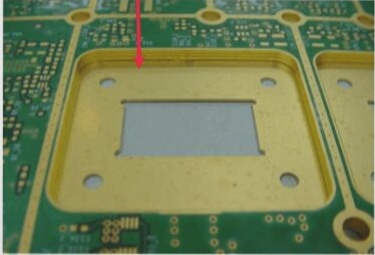

- Heat Dissipation for Power Integrated Circuits: Effective heat dissipation is crucial for power integrated circuits. Always use a heatsink when operating at high power levels to prevent overheating.

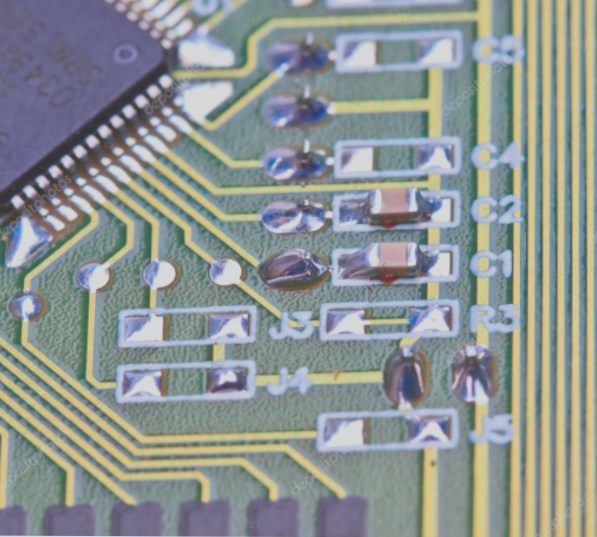

- Soldering Techniques: Ensure proper solder flow to prevent poor connections. Limit soldering time to under 3 seconds with a 25W internally heated soldering iron. Check for short circuits between pins using an ohmmeter before powering on.

- Peripheral Component Addition: When adding peripheral components, choose small components and plan wiring carefully to avoid parasitic coupling. Pay attention to grounding connections between circuits.

- Integrated Circuit Abnormalities: Abnormalities in circuits can lead to voltage fluctuations, but not all fluctuations indicate circuit damage. Be cautious when diagnosing circuit issues.

- Oscilloscope Measurements: When measuring voltages or testing waveforms, avoid causing short circuits between pins by securely placing the probe. Conduct measurements directly on the peripheral printed circuit board.