The concept of the printed circuit board (PCB) was first proposed in patents at the beginning of the 20th century. In 1947, the American Aviation Administration and the American Bureau of Standards organized the first technical seminar focused on printed circuits. At this seminar, 26 different methods for manufacturing printed circuits were identified. These methods were later grouped into six main categories: coating, spraying, chemical deposition, vacuum evaporation, molding, and powder compaction. However, these methods were not yet suitable for large-scale industrial production.

It wasn’t until the early 1950s that significant advancements were made. The problems related to the adhesion of copper foil to the base layer were resolved, improving the stability and reliability of copper-clad laminates. This development enabled the mass production of PCBs. The copper foil etching process eventually became the dominant technique in PCB manufacturing and remains the standard to this day.

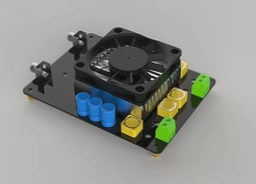

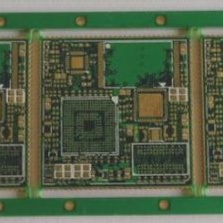

In the 1960s, significant innovations such as hole metallization, double-sided printing, and multi-layer boards were introduced, leading to their mass production. The 1970s saw the emergence of large-scale integrated circuits (LSIs) and electronic computers, which spurred rapid development in the PCB industry. The 1980s brought the rise of surface-mount technology (SMT), while the 1990s saw advancements in multi-chip assembly technology.

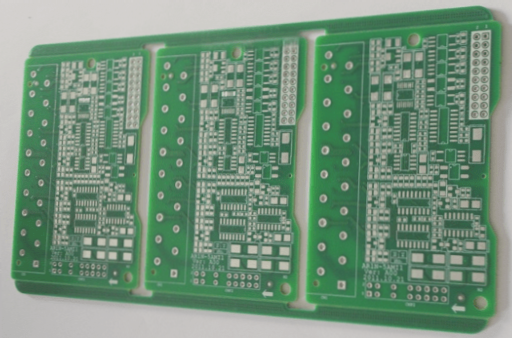

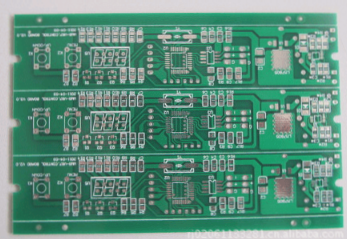

As the PCB industry continued to evolve, new materials, equipment, and testing instruments emerged. This continuous advancement led to the development of high-density, thin-wire, multi-layer, and high-reliability PCBs. The industry also moved toward low-cost, automated continuous production systems, driving the ongoing trend toward innovation in PCB manufacturing. Today, PCBs are a critical component in virtually all electronic devices, and their development continues to push the boundaries of technology.

China’s development of printed circuit boards (PCBs) began in the mid-1950s, initially focusing on single-sided boards used primarily in semiconductor radios. By the mid-1960s, China had independently developed foil-clad laminate substrates, which made copper foil etching the dominant production process for PCBs in the country. During this period, China was able to mass-produce single-sided boards and produce small batches of double-sided boards with metallized holes. It also began exploring the development of multilayer boards on a limited scale.

In the 1970s, China introduced the pattern electroplating etching process to further enhance PCB production. However, the lack of specialized materials and equipment, coupled with various external challenges, caused the country’s PCB production technology to lag behind that of foreign nations. By the 1980s, China’s economic reforms and opening-up policies helped bring in advanced production lines for single-sided, double-sided, and multilayer PCBs. Over the next decade, China rapidly improved its PCB production technology through extensive learning, absorption, and adaptation of foreign technologies.

The 1990s marked a pivotal period for China’s PCB industry, as foreign manufacturers from Hong Kong, Taiwan, and Japan began establishing joint ventures or wholly-owned factories in China. This influx of foreign investment led to a dramatic rise in PCB production and technological development. By 1995, a nationwide survey conducted by the National Printed Circuit Industry Association revealed that there were 459 PCB manufacturers across China. This included 128 state-owned enterprises, 125 collective enterprises, 86 joint ventures, 22 private companies, and 98 foreign-invested firms. The total output of printed boards reached 16.56 million square meters, with 3.62 million square meters of double-sided boards and 1.24 million square meters of multilayer boards. The total sales amounted to 9 billion yuan (approximately US$1.1 billion). According to data from the IPC Association in the United States, the sales of printed circuits in China, including Hong Kong, reached $1.17 billion in 1994, representing 5.5% of the global market share and ranking China as the fourth-largest producer worldwide.

As a result of the large-scale introduction of advanced foreign equipment and technology, China’s PCB industry made significant strides in narrowing the technological gap with foreign counterparts. However, despite these advancements, many Chinese PCB companies remained small in scale, with low per capita annual sales, low industrial productivity, and limited technical capabilities.

In summary, China’s PCB industry underwent significant evolution, transitioning from basic single-sided boards in the 1950s to a more diversified and technologically advanced production landscape by the 1990s. Foreign partnerships and technology transfers played a crucial role in accelerating the country’s PCB capabilities, although challenges such as scale, productivity, and technical expertise remained.

It wasn’t until the early 1950s that significant advancements were made. The problems related to the adhesion of copper foil to the base layer were resolved, improving the stability and reliability of copper-clad laminates. This development enabled the mass production of PCBs. The copper foil etching process eventually became the dominant technique in PCB manufacturing and remains the standard to this day.

In the 1960s, significant innovations such as hole metallization, double-sided printing, and multi-layer boards were introduced, leading to their mass production. The 1970s saw the emergence of large-scale integrated circuits (LSIs) and electronic computers, which spurred rapid development in the PCB industry. The 1980s brought the rise of surface-mount technology (SMT), while the 1990s saw advancements in multi-chip assembly technology.

As the PCB industry continued to evolve, new materials, equipment, and testing instruments emerged. This continuous advancement led to the development of high-density, thin-wire, multi-layer, and high-reliability PCBs. The industry also moved toward low-cost, automated continuous production systems, driving the ongoing trend toward innovation in PCB manufacturing. Today, PCBs are a critical component in virtually all electronic devices, and their development continues to push the boundaries of technology.

China’s development of printed circuit boards (PCBs) began in the mid-1950s, initially focusing on single-sided boards used primarily in semiconductor radios. By the mid-1960s, China had independently developed foil-clad laminate substrates, which made copper foil etching the dominant production process for PCBs in the country. During this period, China was able to mass-produce single-sided boards and produce small batches of double-sided boards with metallized holes. It also began exploring the development of multilayer boards on a limited scale.

In the 1970s, China introduced the pattern electroplating etching process to further enhance PCB production. However, the lack of specialized materials and equipment, coupled with various external challenges, caused the country’s PCB production technology to lag behind that of foreign nations. By the 1980s, China’s economic reforms and opening-up policies helped bring in advanced production lines for single-sided, double-sided, and multilayer PCBs. Over the next decade, China rapidly improved its PCB production technology through extensive learning, absorption, and adaptation of foreign technologies.

The 1990s marked a pivotal period for China’s PCB industry, as foreign manufacturers from Hong Kong, Taiwan, and Japan began establishing joint ventures or wholly-owned factories in China. This influx of foreign investment led to a dramatic rise in PCB production and technological development. By 1995, a nationwide survey conducted by the National Printed Circuit Industry Association revealed that there were 459 PCB manufacturers across China. This included 128 state-owned enterprises, 125 collective enterprises, 86 joint ventures, 22 private companies, and 98 foreign-invested firms. The total output of printed boards reached 16.56 million square meters, with 3.62 million square meters of double-sided boards and 1.24 million square meters of multilayer boards. The total sales amounted to 9 billion yuan (approximately US$1.1 billion). According to data from the IPC Association in the United States, the sales of printed circuits in China, including Hong Kong, reached $1.17 billion in 1994, representing 5.5% of the global market share and ranking China as the fourth-largest producer worldwide.

As a result of the large-scale introduction of advanced foreign equipment and technology, China’s PCB industry made significant strides in narrowing the technological gap with foreign counterparts. However, despite these advancements, many Chinese PCB companies remained small in scale, with low per capita annual sales, low industrial productivity, and limited technical capabilities.

In summary, China’s PCB industry underwent significant evolution, transitioning from basic single-sided boards in the 1950s to a more diversified and technologically advanced production landscape by the 1990s. Foreign partnerships and technology transfers played a crucial role in accelerating the country’s PCB capabilities, although challenges such as scale, productivity, and technical expertise remained.