Effective PCB Debugging Methods for New Circuit Boards

When dealing with a newly designed circuit board, debugging can be a challenging task, especially for larger boards with numerous components. However, having a systematic approach to debugging can significantly improve efficiency.

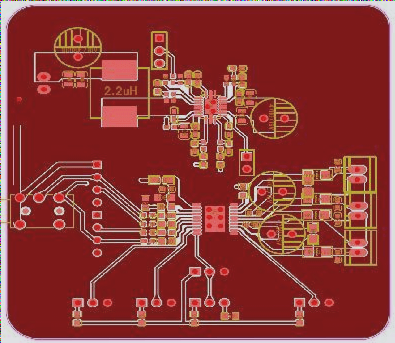

Initial Inspection and Component Installation

- Start by visually inspecting the board for any visible issues like cracks, short circuits, or open circuits.

- Check the resistance between the power supply and ground wire.

- Install components methodically, starting with independent modules installed one by one to verify functionality.

- For smaller circuits, components can be installed simultaneously to quickly identify faults.

Power Supply Testing

After component installation, focus on testing the power supply:

- Begin by installing the power supply and checking the output voltage when powered on.

- Consider using an adjustable regulated power supply with current limiting and overcurrent protection.

- Gradually increase the voltage while monitoring parameters to ensure proper functionality.

Fault Finding Methods

Various methods can be employed to identify faults in the circuit:

- Voltage Measurement: Check the power supply pins of each chip for normal voltage levels.

- Sensory Inspection: Observe for mechanical damage, unusual sounds, smells, and abnormal temperatures during operation.

- Signal Injection: Apply a signal source to the input terminal and measure waveforms to pinpoint faults.

WellCircuits Limited: Leading PCB Manufacturer

WellCircuits Limited specializes in high-precision circuit boards, offering a wide range of products to meet diverse customer requirements:

- HDI PCBs

- Backplanes

- Rigid-flex boards

- Buried capacitance boards

- Buried resistance boards

- Golden Finger boards