**PCB Through-Hole Solder Paste**

Past-In-Hole (PIH) involves printing solder paste directly onto the Plated Through Holes (PTH) of the Printed Circuit Board (PCB). Subsequently, traditional plug-in or through-hole components (DIP components) are inserted into the solder paste-coated PTHs. During this process, most of the solder paste adheres to the leads of the inserted components. When subjected to the high temperatures of the reflow oven, the solder paste melts, securely soldering the components to the circuit board.

This technique is also referred to as “pin-in-paste,” “intrusive reflow soldering,” and “reflow of through-hole” (ROT), among other names.

The primary advantage of this method is the elimination of hand soldering or wave soldering processes, resulting in significant labor savings. Additionally, it enhances soldering quality and reduces the risk of solder shorts.

However, this method comes with certain inherent limitations:

1. The thermal resistance of traditional components must meet the reflow soldering temperature requirements. Generally, plug-in components are made from materials with lower temperature tolerances than those used in reflow soldering. Since the PIH method necessitates that traditional components undergo reflow alongside standard SMT components, they must be capable of withstanding temperatures of up to 260°C for 10 seconds, especially for lead-free components.

2. It’s preferable to use tape-on-reel packaging (tape-on-reel) and ensure there’s sufficient flat surface to place components on the circuit board (PCB) via the SMT pick and place machine. If this setup fails, it may be necessary to deploy an additional operator for manual placement of the components. During this process, it’s important to assess the required working hours and the potential for quality issues, as manual insertion can inadvertently disturb other positioned components due to careless handling.

3. The solder pads for the component body and the PCB should feature a standoff (elevated) design. Typically, the PIH process involves printing the solder paste larger than the outer frame of the solder pad. This approach is intended to enhance the amount of solder paste used, aiming for 75% of the through-hole filling requirement. Without a standoff between the component and the solder pad, the molten solder paste can flow through the gap during reflow, leading to excess solder and solder balls, which may compromise future electrical performance.

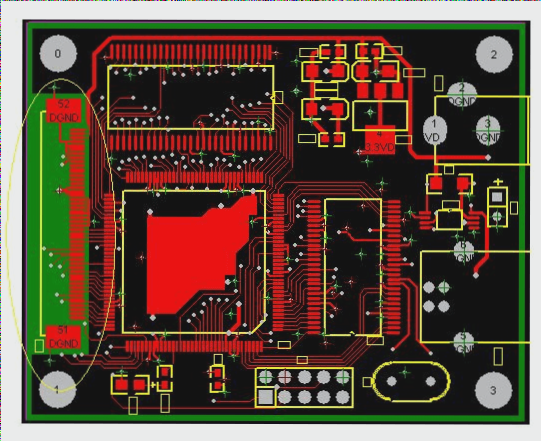

4. For traditional components, it is advisable to print solder paste on the second side (if using double-sided SMT). If components are printed on the first side, proceeding with SMD on the second side may cause solder paste to flow back into the traditional components, increasing the risk of internal short circuits, particularly with connectors. Additionally, the quantity of solder remains the most significant challenge with this approach. According to IPC-610 standards, through-hole solder joints should exceed 75% of the thickness of the PCB, with some requirements being at least 50%. (Refer to the figure below and IPC-610 section 7.5.5.1 for detailed specifications.)

Regarding the calculation of solder paste volume, you can determine it by subtracting the smallest pin diameter from the maximum through-hole diameter, then multiplying by the PCB thickness. Remember to multiply by 2 again, as the flux in the solder paste comprises 50%, meaning that after reflow, the volume of solder paste will reduce to half of the initially printed amount.

The required solder paste volume ≧ [(Maximum diameter of the through hole/2)² – (Minimum diameter of the pin/2)²] * π * thickness of the circuit board * 2.

To increase the solder volume in through-holes, consider the following methods:

1. Allow adequate space around the PCB through-hole (PTH) for overprinting.

Consult with the Layout Engineer (PCB layout engineer) to create additional space for solder paste printing near the through-holes requiring paste-in-hole. This will help prevent short circuits during overprinting. It’s important to note that the flat area for solder paste printing cannot extend indefinitely; the cohesive properties of the solder paste must be taken into account to ensure it can fully retract from the solder pads and avoid forming solder beads. Additionally, ensure that the direction of solder paste printing aligns with the extension direction of the solder pads.

2. Reduce the diameter of the through-hole on the circuit board.

As noted in the previous calculation, a larger through-hole diameter requires more solder paste. However, it’s essential to consider that if the diameter is too small, it may hinder the insertion of components.

3. Utilize step-up (partial thickening) or step-down (partial thinning) stencils (steel plates).

These stencils can locally increase the thickness of solder paste, thereby boosting the amount applied and fulfilling the requirement for filling through-holes. However, note that such stencils tend to be about 10% more expensive than standard options.

4. Adjust the appropriate solder paste, along with the speed and pressure of the printing machine, and the type and angle of the squeegee.

These settings on the solder paste printer can influence the volume of solder paste printed. Solder paste with lower viscosity will typically result in a greater amount being applied.

5. Add additional solder paste.

Consider using a dispenser to apply extra solder paste on the paste-in-hole pads to increase the volume. While fully automated dispensers are scarce in current PCB production lines, manual dispensing is a viable alternative, albeit requiring additional operator hours.

6. Employ solder preforms.