Understanding Printed Circuit Boards (PCB)

What is a Printed Circuit Board?

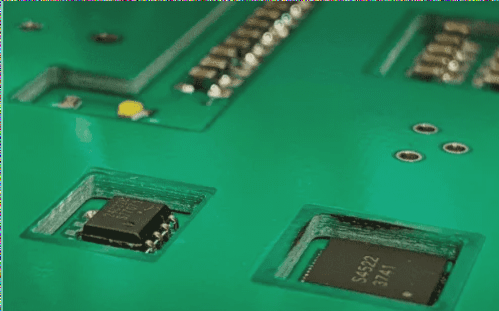

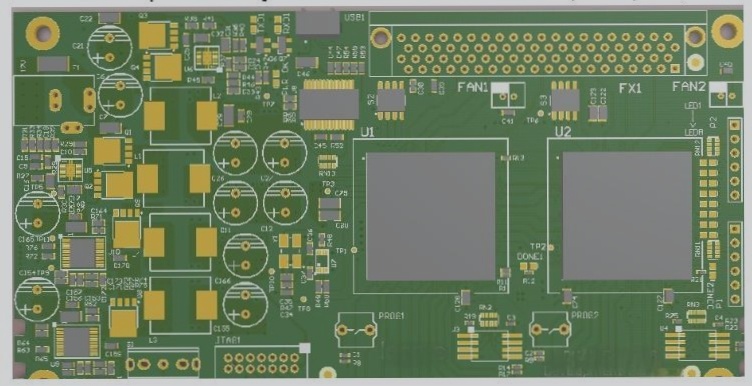

A Printed Circuit Board (PCB) is a board that contains conductive patterns created from printed circuits, printed components, or a combination of both on an insulating material. These conductive layouts facilitate electrical connections between components on the board.

Importance of PCBs

PCBs are essential components in electronic devices, ranging from electronic watches and calculators to personal computers, communication equipment, and even military weapon systems. They provide mechanical support for electronic components, facilitate wiring and electrical connections, and ensure necessary electrical characteristics.

How Are PCBs Made?

PCBs are manufactured using a variety of materials and processes. They can be single-sided, double-sided, or multilayered boards, with different substrates and conductive materials used based on the specific application. The production process involves mechanical processing, chemical reactions, and various other specialized techniques.

Challenges in PCB Production

The production of PCBs is complex and can be challenging due to the wide range of operations involved. Process engineers face pressure to address issues that may arise during production, as any problem can lead to production halts or waste. Despite the challenges, PCBs remain crucial components in modern electronic devices.

If you have any PCB manufacturing needs, feel free to contact us for assistance.