SMD Stencil and Alignment Techniques

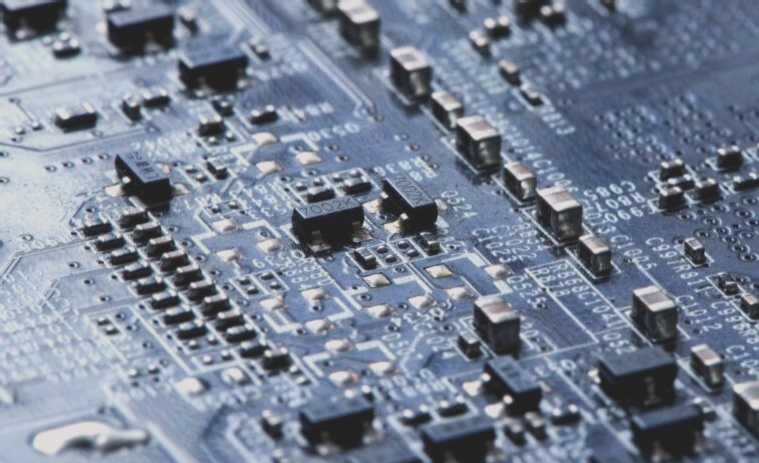

Surface-mount components require precise solder paste application using a stencil. This thin stainless steel screen ensures accurate paste printing on the PCB.

Manual alignment of the stencil over the pads is possible if a stencil printer is unavailable. Secure the stencil with tape to prevent movement during paste application.

For finer-pitched components, like 0.5mm or 0.4mm, achieving perfect alignment manually becomes more challenging.

Using Alignment Pins for Precision

Aligning the stencil with pins provides accuracy. Start by measuring the pin diameter, then create a pin library in KiCad’s Footprint Editor for integration into your design.

Position the pin footprints at the PCB corners for precise stencil alignment.

Your pin library is now equipped with 1mm diameter holes and 1mm solder mask clearance for accurate alignment.

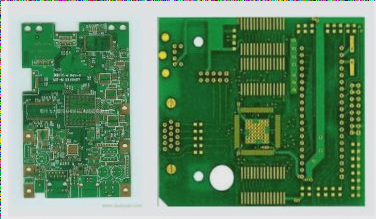

Ordering a Custom Stencil

Order stencils conveniently with your PCB from WellCircuits. Specify “lasered through” for fiducials to avoid missing holes.

- Stencil type: Non-framework

- Fiducials: Lasered through

Consider ordering a stencil size slightly larger than the PCB for easier handling during assembly.

Mastering Solder Paste Printing for Perfect PCB Assembly

When it comes to PCB assembly, precision is key. Solder paste printing is a crucial step in ensuring the success of your circuit board. Here’s how you can master this process:

1. Verify Hole Alignment

- Check that the holes in the board align with the pins for accurate placement.

2. Prepare Solder Paste

- Set up your work area and ensure all materials are ready for use.

3. Position the Stencil

- Secure the stencil on top of the PCB using pins for precise alignment.

4. Align Pads and Holes

- Insert pins to align the PCB pads with the stencil holes, ensuring accuracy.

5. Apply Solder Paste

- Use a card to apply solder paste to the pads, guaranteeing proper placement.

By following these steps, you can achieve flawless solder paste printing on your PCB, leading to a successful assembly process.