The Ultimate Standalone H-Bridge DC Motor Driver

The Full-Bridge (H-Bridge) is a popular driver circuit for controlling brushed DC motors, offering the unique ability to change the motor’s rotation direction effortlessly. Responding to demands, a compact and affordable standalone H-Bridge DC motor driver has been developed, eliminating the need for external controllers.

Key Features:

- Controlled by an ATTiny13 microcontroller

- Allows motor control in Forward, Stop, and Reverse modes

- Independent speed adjustment for forward and reverse directions

- Handles higher currents with low MOSFET ON-resistance

Recent Updates:

For the schematic and PCB design, Altium Designer 22 was utilized. The Octopart search engine facilitated component data gathering and BOM generation. High-quality PCB fabrication was entrusted to WellCircuits, using Gerber files. Testing involved repurposing a toy car motor with a powerful 775 DC motor and gearbox.

Specifications:

- Input Voltage (Motor): 8-40VDC

- Supply Voltage (Controller): 12VDC

- PWM Frequency: 25KHz

- Motor Control: Forward-Stop-Reverse

- Motor Speed: [0 to 100%] Forward, [0 to 100%] Reverse

To order a fully assembled PCB board with free shipping, contact info@wellcircuits.com.

Circuit Analysis:

Figure 1 illustrates the schematic of the standalone full-bridge DC motor driver, comprising the H-Bridge driver, microcontroller, and supply regulator.

Microcontroller: The ATTiny13 microcontroller (IC1) manages the H-Bridge section, with decoupling capacitors (C1, C2) for noise filtration. Potentiometers (P1, P2) adjust motor speed, while connectors (P3, P4) interface with a 3-position switch for direction control.

Supply Regulator: The 78L05 regulator chip (REG1) and components (R4, C6, D1, R5, C7, C8) maintain stable supply voltage.

H-Bridge Driver: The core driver component for motor control.

High-Power D2Pack IRF3205 MOSFETs in H-Bridge Circuit

- Q1 to Q4: High-power D2Pack IRF3205 MOSFETs make up the H-Bridge circuit.

- Diodes D4 to D7 provide protection against reverse inductive currents from the motor.

- Include diodes for added safety.

- R6, R7, R8, and R10 are current-limiting resistors for the gate pins.

- IC2 and IC3 are IR2104 half-bridge driver ICs.

- C12 and C13 are decoupling capacitors.

- R9 and R11 are pull-down resistors to prevent unwanted triggering of the driver ICs.

- C9 reduces supply noise from the motor, especially during startup.

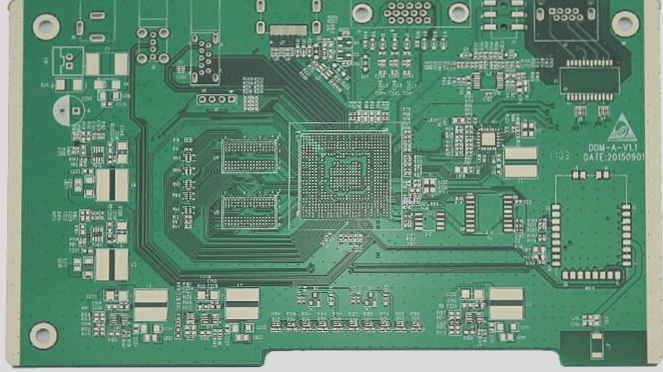

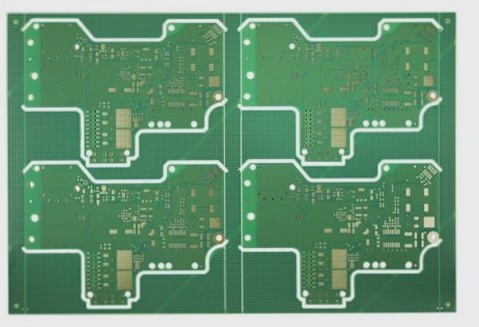

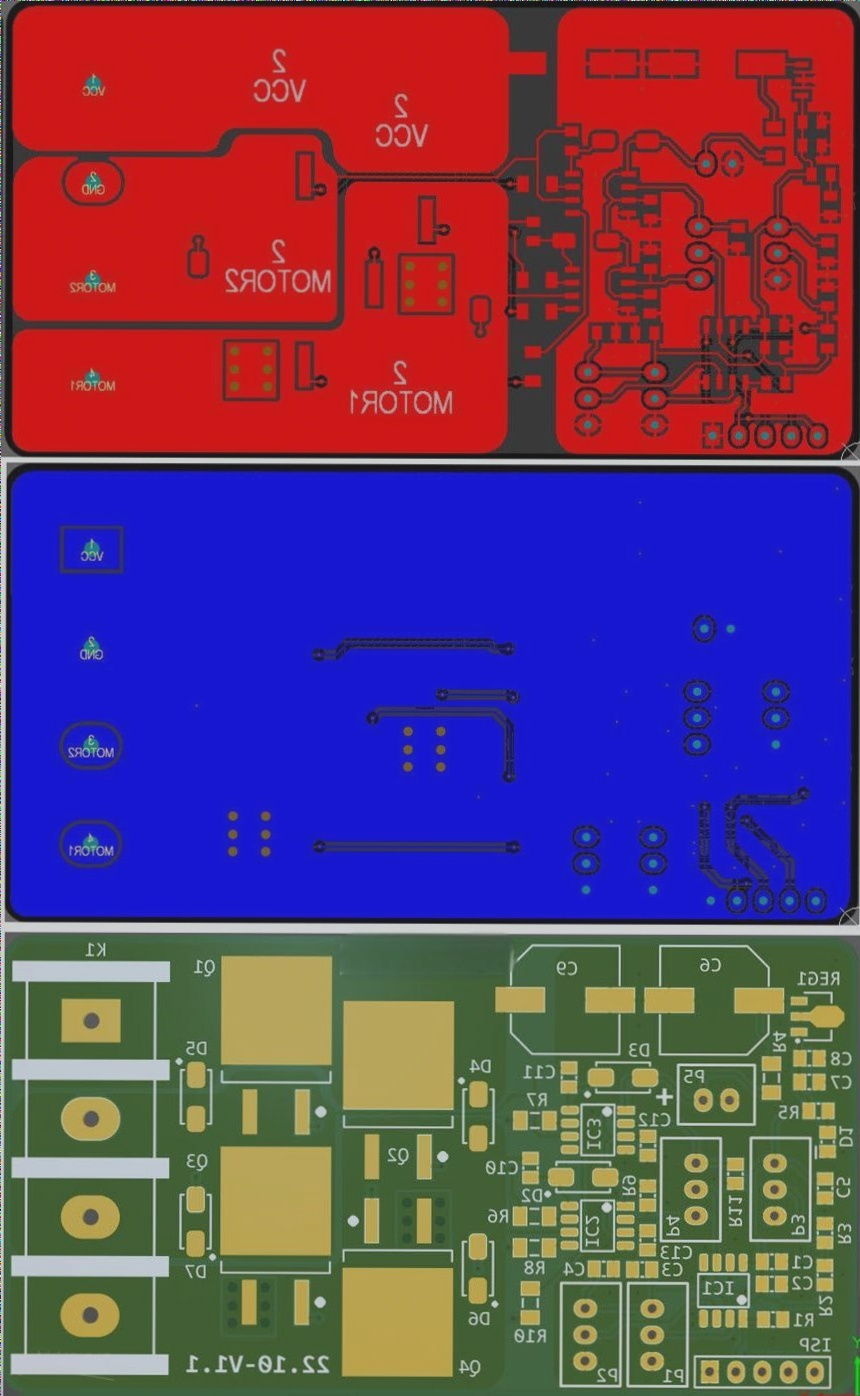

PCB Layout

The PCB layout of the device is shown in Figure 3. It is a two-layer PCB with all SMD components, except for the connectors, making it compact and easy to integrate into enclosures. Assembly drawings of the PCB are illustrated in Figure 4.

Figure 3

PCB layout of the Standalone Full Bridge DC Motor Driver (Altium)

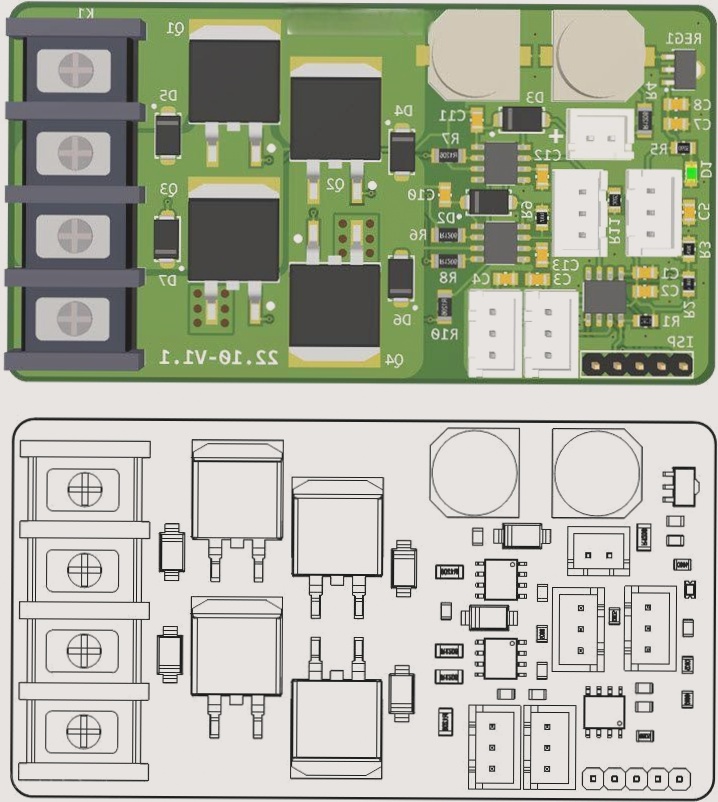

Figure 4

Assembly drawings of the PCB board

Code

The code for this project was developed using the Arduino IDE and the MicroCore hardware package for ATTiny13 [5]. To compile the code for ATTiny13, ensure you have installed this package. A compiled HEX file [6] is provided for your convenience. You will need an AVR ISP programmer like USBasp to burn the HEX file onto the ATTiny13. Set the fuse bits for a 9.6 MHz internal clock with no clock division (division = 1). The ISP programming pinout is shown in Figure 5.

#include <util/delay.h> // Clock at 9.6MHz #define F_CPU 9600000 const int PWMPin = 1; analog_pin_t FVOLPin = A3; analog_pin_t RVOLPin = A