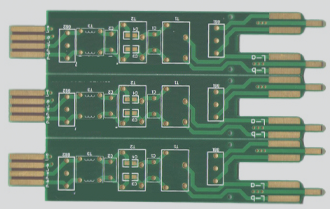

What is the quality standard for PCBA processing? What factors should be evaluated when accepting PCBA products? Below are the acceptance criteria for PCBA processed items:

1. Inspection Environment:

1. Inspection environment: temperature: 25±3 degrees Celsius, humidity: 40-70% RH.

2. Appearance evaluation should be conducted from a distance of 1 meter under a 40W fluorescent lamp (or equivalent light source), with the inspected product positioned 30 cm away from the inspector.

2. Sampling Level:

QA sampling standard: adhere to the GB/T 2828.1-2003 level II inspection one-time sampling plan.

AQL values: CR: 0, MAJ: 0.25, MIN: 0.65.

This maintains the original meaning and clarity while slightly adjusting the phrasing.

3. Inspection equipment:

BOM list, magnifying glass, feeler gauge, patch location map

4. Acceptance criteria:

1. Reverse:

The polarity mark (white silkscreen) on the component aligns with the diode silkscreen on the PCB (acceptable).

The polarity mark (white silkscreen) on the component does not match the diode silkscreen on the PCB (rejected).

2. Excessive solder:

The maximum height of the solder joint (E) may exceed the PAD or reach the top of the metal plating on the solderable end cap, but must not contact the component body (acceptable).

The solder has made contact with the top of the component body (rejected).

3. Reverse:

For exposed and stored electrical materials, chip components may be mounted with the material surface opposite the printed surface, allowing only one component ≤ 0402 per board to be reversed (acceptable).

If multiple components ≤ 0402 per board are mounted with the same orientation as the printed surface, this will be highlighted (rejected).

4. Air welding:

The solder joints between component pins and the PAD are well-formed and complete, with no warping of component pins (acceptable).

If the component pin arrangement is not coplanar, it will hinder proper soldering (rejected).

5. Cold welding:

The solder paste flows completely during reflow, resulting in shiny, fully wetted solder joints (acceptable).

If the solder paste on the solder ball is not fully reflowed, showing dark, irregular surfaces and unmelted tin powder, it will be rejected (rejected).

6. Insufficient components:

The BOM list specifies a required placement number for certain components, which were not placed (rejected).

If the BOM list indicates that a certain placement number is unnecessary but components are found, creating redundancy in prohibited areas, this will also be rejected (rejected).

7. Damaged components:

Edge peeling should be less than 25% of the component width (W) or thickness (T), with a maximum of 50% metal plating loss at each end (acceptable).

Any cracks, nicks, or damage exposing the internal structure, as well as any defects in the resistive material or glass element body, will lead to rejection (rejected).

8. Blistering and delamination:

The area affected by blistering and delamination should not exceed 25% of the spacing between plated through holes or internal conductors (acceptable).

If blistering and delamination exceed 25% of the spacing, compromising the minimum electrical clearance, this will be rejected (rejected).

By strictly adhering to acceptance procedures, we can ensure the quality of PCBA processed products. Focusing on quality is essential for survival in an increasingly competitive market.

Let me know if you need any further adjustments!