Factors Affecting PCB Copy Accuracy

The accuracy of a PCB copy is determined by two main factors: the precision of the software used and the quality of the original image. Different PCB copy companies offer varying levels of accuracy based on their technical capabilities.

Software Precision

When it comes to PCB copying, the precision of the software plays a crucial role. Using 32-bit floating point representation in software generally imposes no accuracy limits. However, the primary factor influencing accuracy is the quality of the original image scan.

Image Quality

For highly accurate PCB reproduction, the image quality of the original scan is paramount. Just like printing a high-resolution image, scanning a PCB at a higher DPI (dots per inch) is essential for capturing intricate details accurately.

DPI and Accuracy

DPI, which stands for “dots per inch,” determines the resolution of a scanned image. The higher the DPI, the clearer and more accurate the image reproduction. It is recommended to choose a DPI setting above 1000 for precise PCB copying, especially for intricate circuit designs.

Impact of DPI Setting

Choosing the right DPI setting ensures the accuracy of the copied PCB. While higher DPI results in greater accuracy, it also increases file size and hardware demands. For general PCB accuracy, 400 DPI is sufficient, but for intricate designs like mobile phone PCBs, a DPI setting above 1000 is recommended.

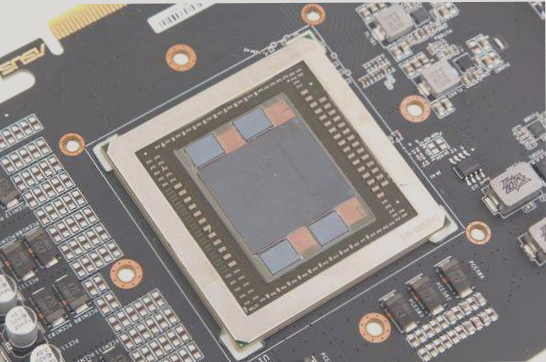

PCB Energy Storage Capacitors

Types of Energy Storage Capacitors

PCB energy storage capacitors play a crucial role in maintaining stable power supply voltage, especially during rapid load changes. These capacitors are categorized into system-level, board-level, and device-level capacitors.

System-Level Capacitors

System-level energy storage capacitors collect and transfer stored energy to the power supply output. Components like aluminum electrolytic capacitors are commonly used, with voltage ratings between 40V and 450V (DC) and capacitances ranging from 220 μF to 150,000 μF.

Board-Level Capacitors

Board-level capacitors ensure voltage stability on the PCB during load changes. Large-capacity tantalum capacitors are placed on high-frequency PCBs to maintain consistent voltage levels.

Device-Level Capacitors

Device-level capacitors stabilize voltage around specific components, preventing drops during load fluctuations. Placing large-capacity tantalum capacitors near the device is recommended for devices with high operating frequencies.

Guidelines for Placement

- Near the power supply connector input

- Close to power terminals connecting daughter boards, peripherals, and auxiliary circuits

- Near high-power digital components

- Furthest from the power input terminal

- In component-dense areas away from power supply digital terminals

- Close to the clock generation circuit