Effective Strategies to Prevent ESD in PCB Design

Static electricity poses a significant threat to sensitive components on a Printed Circuit Board (PCB). Employing techniques like layering, thoughtful layout, and strategic installation during the design phase can greatly reduce the risk of electrostatic discharge (ESD) damage. Optimizing the layout and routing is the most effective strategy for ESD protection, offering substantial benefits in preventing potential damage.

Sources of Static Electricity and Impact on Components

- Static electricity can originate from various sources such as the human body, environmental factors, and electronic devices, leading to harm to precision semiconductor chips in multiple ways:

- – Penetrating the insulating layer inside components

- – Damaging MOSFET and CMOS component gates

- – Locking triggers within CMOS devices

- – Causing short circuits in PN junctions

- – Melting solder or aluminum wires inside active devices

To safeguard electronic equipment from ESD-related damage, effective measures must be implemented throughout the design and manufacturing process.

Effective Strategies for ESD Damage Prevention

- Layering: Use multiple layers to separate sensitive signal paths from high-voltage areas.

- Appropriate Layout: Ensure proper component placement to reduce ESD events and improve grounding.

- Installation of Protective Components: Include ESD protection devices like diodes or resistors to dissipate static charge safely.

Significance of Layout and Routing

Adjusting the PCB layout and routing is the most effective method to prevent ESD. By planning component placement and trace routing carefully, exposure to potential static discharge can be minimized, including routing signal traces away from high-voltage areas and ensuring proper grounding and shielding.

By incorporating these design principles, ESD risks can be mitigated, enhancing PCB reliability and device longevity.

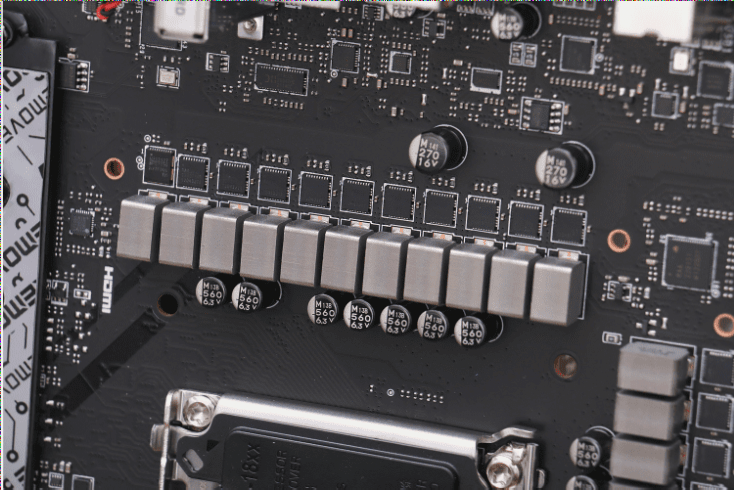

Best Practices for Multi-Layer PCB Design and Grounding Techniques

- Maximize the Use of Multi-Layer PCBs: Multi-layer PCBs provide advantages in reducing electrical interference by incorporating dedicated ground and power planes.

- Signal Layer Placement and Power/Ground Layer Proximity: Place signal layers close to corresponding power or ground planes to minimize impedance and crosstalk between signal traces.

- Power and Ground Grid Design: Implementing a robust power and ground grid design is crucial for optimal PCB performance.

Key Strategies for Effective Multi-Layer PCB Design

-

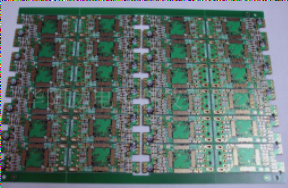

Power and Ground Grid Structure

Utilize tightly interwoven power and ground planes, with close proximity between power and ground lines. Opt for a grid size no larger than 60mm, ideally 13mm or smaller for enhanced signal performance.

-

Compact Circuit Design

Ensure a compact layout by minimizing trace lengths and vias. Place connectors along the PCB edges to optimize signal trace and power distribution efficiency.

-

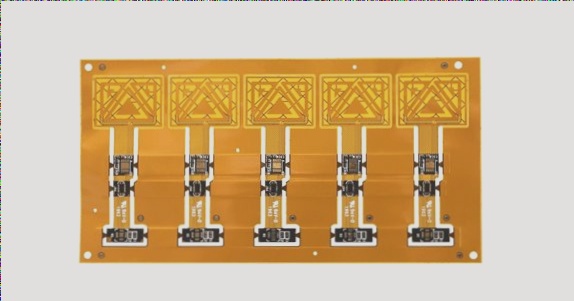

Power Entry and ESD Protection

Lead power lines into the PCB away from Electrostatic Discharge (ESD) vulnerable areas to safeguard against ESD interference.

-

Chassis Grounding for ESD Protection

Implement a wide chassis ground beneath external connectors to create a low-impedance return path for ESD energy, reducing the risk of component damage.

-

Mounting Holes and Ground Connections

Position mounting holes along the PCB edge, connect them to chassis ground, and avoid soldering pads around the holes for a secure connection.

-

Isolation Between Circuit and Chassis Grounds

Maintain an isolation zone between circuit and chassis grounds, ensuring a separation distance of at least 0.64mm to prevent unintentional coupling. Connect chassis and circuit grounds on the top and bottom layers near mounting holes for effective grounding.

By following these best practices, you can enhance the performance, reliability, and signal integrity of your PCB designs, minimizing noise interference and ensuring efficient grounding.