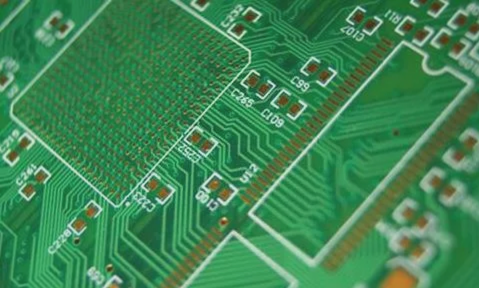

2. As the data transmission speed of notebook computers continues to increase, the demand for flexible PCB substrates with high-speed transmission characteristics is also rising. Consequently, managing the characteristic impedance values of flexible PCB substrates has become essential.

3. Flexible PCB substrates are classified into two categories: single-sided and double-sided. For notebook computers, the signal and ground layers are typically implemented as double-sided flexible PCB substrates made of copper foil. This configuration is preferred due to the need to manage different characteristic impedance values.

1. Management is simpler, particularly when dealing with a single-sided flexible PCB substrate. Once this substrate comes into contact with the chassis, its dielectric constant is influenced by the contacting object, leading to changes in characteristic impedance. Thus, it’s crucial to consider the surrounding environment of the flexible PCB substrate. Consequently, managing a single-sided flexible PCB is more complex compared to a double-sided flexible PCB substrate.

2. This article will explore in detail the lightweight nature of flexible PCB substrates and the high-speed transmission technology necessary to meet data transmission requirements.

3. **Lightweight Technology**

4. The primary approach to developing lightweight flexible PCB substrates involves significantly simplifying the structure of traditional double-sided flexible PCBs used in notebooks. Specifically, conductive glue is applied to create a ground layer on the surface of a single-sided flexible PCB, mimicking a pseudo double-sided structure.

5. A comparison between the traditional double-sided flexible PCB substrates and the lightweight flexible PCB substrates reveals the following:

6. **Lightweight**

7. In a double-sided flexible PCB substrate, the signal layer and the ground layer are electrically connected via copper coating. This results in a relatively high copper content overall.

8. In contrast, the lightweight flexible PCB substrate uses a ground layer created by filling openings in the protective layer with conductive glue, which connects to the signal layer. This effectively eliminates the need for copper coating, which is detrimental to quality. Moreover, the lightweight flexible PCB substrate can achieve a 50% reduction in weight compared to its double-sided counterpart.

9. **Thinning and Flexibility**

10. The lightweight flexible PCB substrate, being essentially single-sided and without copper foil coating, achieves a 28% reduction in thickness compared to double-sided flexible PCB substrates. Additionally, its flexibility improves by 89%, allowing for the creation of complex and fine designs that can navigate inside notebook computer chassis without curling.

11. **Transmission Characteristics of Lightweight FPC**

12. Lightweight flexible PCB substrates are now used in parts of notebook computers that interface with S-ATA1 (communication speed 1.5 Gbit/s) hard disk drives. Currently, S-ATA1 is being replaced by S-ATA2 (communication speed 3.0 Gbit/s), with future evolution expected to S-ATA3 (communication speed 6.0 Gbit/s). Therefore, lightweight flexible PCB substrates must be designed to support these advancements in high-speed transmission.

13. The impedance characteristics of the lightweight flexible PCB substrate are illustrated in the figure. As the length of the transmission line increases, transmission loss eventually occurs.

14. Simulation analysis of the waveform for the lightweight flexible PCB substrate shows that the eye pattern does not reach the reference for S-ATA1, indicating a good waveform in the central hexagonal area. In contrast, the eye pattern for S-ATA2 touches the central hexagonal area, significantly reducing symbol recognition margins. This demonstrates the necessity of the lightweight flexible PCB substrate for improving transmission characteristics as data speeds increase in the future.