The memory structure is simple, primarily composed of DRAM ICs and PCB boards. Therefore, the distinction between high-end and low-end memory largely hinges on these two components.

The DRAM IC, which constitutes a significant portion of memory costs, needs no elaboration on its importance. However, among the few components of memory, the PCB also plays a crucial role in memory performance.

When examining the details of some high-end memory products, one often encounters descriptions such as “8-layer PCB” or “10-layer PCB.” What exactly do these specifications signify? And why do they indicate that memory with more layers of PCB material is more advanced and offers better performance? Today, let’s delve into the layers of PCB to understand their significance.

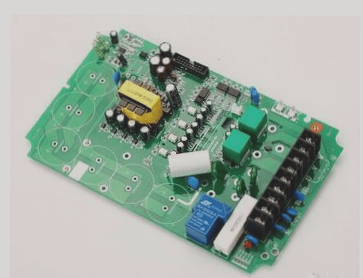

PCB stands for Printed Circuit Board, which is akin to a printed wiring board. Essentially, it replaces actual wires of varying lengths with metal traces on a resin board, significantly reducing wire usage, conserving space, and lowering energy consumption.

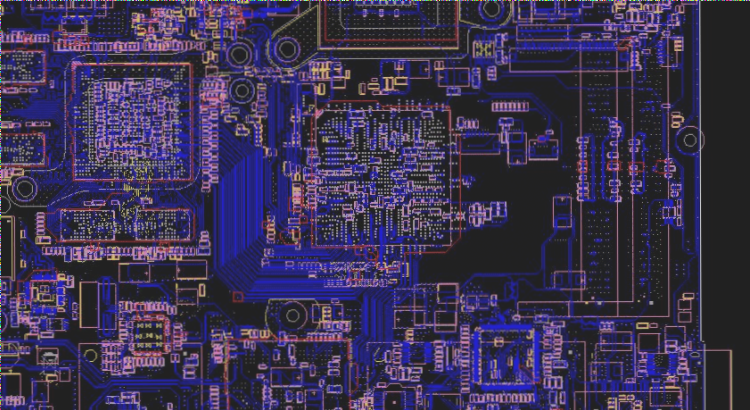

As mentioned earlier, PCBs are constructed by laminating several layers together, each consisting of a resin insulating substrate and a metal circuit layer.

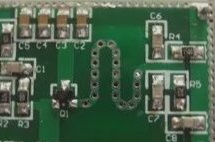

The most basic PCB is divided into 4 layers. The top and bottom layers house the functional circuits where critical components are strategically placed. Sandwiched between them are the middle two layers: the ground layer and the power layer. This design configuration offers significant advantages such as signal integrity correction and enhanced interference shielding.

In general, a 4-layer PCB suffices for standard operations. The addition of layers—such as 6, 8, or 10 layers—enhances the electrical capabilities of the PCB, specifically its power-handling capacity. Therefore, increasing the layer count enables more intricate circuit designs.

The GALAXY HOF2DDR4-4000 memory utilizes a custom 10-layer white PCB to ensure stable electrical supply during memory operations. Enhanced by Samsung B-die technology, it supports robust overclocking capabilities, achieving speeds exceeding 4600MHz. Inspired by the Silver Warrior, its rugged design features a vibrant seven-color breathing light effect, adding to its appeal. For gamers, the HOF II DDR4 series represents a blend of internal excellence and striking external design, making it a preferred choice not just for quality but also for its symbolic value.

When considering memory requirements, the need for additional PCB layers becomes evident under conditions of heightened electrical demands. During overclocking, for instance, memory modules require increased voltage and current to achieve optimal performance. Hence, a higher layer count PCB is essential to accommodate these requirements.

Presently, high-end memory modules often start at frequencies of 3600MHz. To ensure safety and electrical stability, 8-layer PCBs have become standard, with some configurations extending to 10 layers. While the performance variance between 8 and 10-layer PCBs may be negligible for typical users, professional overclockers benefit significantly from the latter, enabling them to attain higher operating frequencies.

The DRAM IC, which constitutes a significant portion of memory costs, needs no elaboration on its importance. However, among the few components of memory, the PCB also plays a crucial role in memory performance.

When examining the details of some high-end memory products, one often encounters descriptions such as “8-layer PCB” or “10-layer PCB.” What exactly do these specifications signify? And why do they indicate that memory with more layers of PCB material is more advanced and offers better performance? Today, let’s delve into the layers of PCB to understand their significance.

PCB stands for Printed Circuit Board, which is akin to a printed wiring board. Essentially, it replaces actual wires of varying lengths with metal traces on a resin board, significantly reducing wire usage, conserving space, and lowering energy consumption.

As mentioned earlier, PCBs are constructed by laminating several layers together, each consisting of a resin insulating substrate and a metal circuit layer.

The most basic PCB is divided into 4 layers. The top and bottom layers house the functional circuits where critical components are strategically placed. Sandwiched between them are the middle two layers: the ground layer and the power layer. This design configuration offers significant advantages such as signal integrity correction and enhanced interference shielding.

In general, a 4-layer PCB suffices for standard operations. The addition of layers—such as 6, 8, or 10 layers—enhances the electrical capabilities of the PCB, specifically its power-handling capacity. Therefore, increasing the layer count enables more intricate circuit designs.

The GALAXY HOF2DDR4-4000 memory utilizes a custom 10-layer white PCB to ensure stable electrical supply during memory operations. Enhanced by Samsung B-die technology, it supports robust overclocking capabilities, achieving speeds exceeding 4600MHz. Inspired by the Silver Warrior, its rugged design features a vibrant seven-color breathing light effect, adding to its appeal. For gamers, the HOF II DDR4 series represents a blend of internal excellence and striking external design, making it a preferred choice not just for quality but also for its symbolic value.

When considering memory requirements, the need for additional PCB layers becomes evident under conditions of heightened electrical demands. During overclocking, for instance, memory modules require increased voltage and current to achieve optimal performance. Hence, a higher layer count PCB is essential to accommodate these requirements.

Presently, high-end memory modules often start at frequencies of 3600MHz. To ensure safety and electrical stability, 8-layer PCBs have become standard, with some configurations extending to 10 layers. While the performance variance between 8 and 10-layer PCBs may be negligible for typical users, professional overclockers benefit significantly from the latter, enabling them to attain higher operating frequencies.