1. Insisting on intelligent manufacturing is the only way for a company to survive.

2. With the rise of technologies like the Internet of Things and cloud computing, the global manufacturing industry is transitioning to an era of digitization and intelligence.

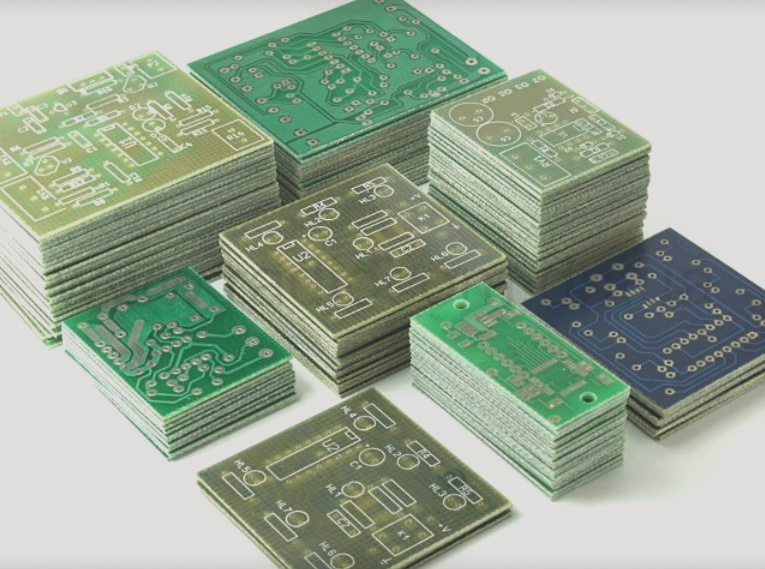

3. In particular, the development of intelligent manufacturing for PCBA patch proofing—an essential technology for the Internet of Things—is also driving advancements in other industries.

4. However, overall, China’s manufacturing industry is large but not strong, with relatively weak independent innovation capabilities, high resource consumption, excessive low-end production capacity, and a clear shortage of high-end supply.

5. The entire industry remains at the middle and low end of the global manufacturing chain.

6. The Nineteenth National Congress report highlighted the need to accelerate the development of the manufacturing industry, promote advanced manufacturing, and integrate the Internet, big data, artificial intelligence, and the real economy.

7. Given the current context of domestic energy transitions and intensifying international competition, advancing intelligent manufacturing is crucial for achieving the strategic goal of becoming an industrial power.

1. Without automation, intelligence cannot be achieved. To realize intelligent manufacturing, we must integrate process technology, material technology, equipment technology, and fundamental manufacturing technology. The future competition will center around products, services, and increasingly, costs. By optimizing production processes and incorporating smart equipment, intelligent manufacturing will enable companies to significantly reduce production, operation, and management costs through advanced computing models and automated operations. This will improve production efficiency and enhance overall competitiveness.

2. We not only anticipate the development of smart manufacturing but are committed to advancing it continually. Our strategy includes “going out” to embrace external opportunities, share knowledge, and pursue win-win cooperation. As previously mentioned, for China to transition from a major manufacturing country to a manufacturing powerhouse, it must vigorously develop smart manufacturing both within enterprises and at the foundational level of the industry. For instance, the intelligent manufacturing of PCBA patch proofing has already begun.

3. The shift from poverty to change, from change to commonality, and from commonality to strength is evident. With the gradual progress in the PCBA manufacturing industry, China’s manufacturing will once again achieve self-sufficiency, eliminating the need to import items such as toilets from Japan, which are neither convenient nor aesthetically pleasing. Chinese-made toilets now offer comfort and functionality, and you no longer need to rely on friends to bring back bone-cutting knives from Germany—Chinese kitchen knives now handle bone cutting effortlessly. In the future, Chinese companies will place greater emphasis on product quality and service: ensuring the highest quality and meticulous service.

4. As the middle class continues to expand, manufacturing companies that do not evolve in terms of quality and service will face significant challenges.

5. New Consumption Concepts: The implementation of Made in China 2025 will greatly enhance product quality. Consequently, production will shift from being reliant solely on worker skills and emotions to utilizing precise and stable automated machinery, integrated software and hardware production methods, and a scientifically managed system.

6. The high-level integration of informatization and industrialization involves driving industrialization with informatization, promoting informatization through industrialization, and charting a new path for industrialization. The core of this integration is to use informatization as a support point and to pursue a sustainable and rapid development model. This involves comprehensively implementing the strategic goals of Made in China 2025, from basic PCBA patch proofing to intelligent manufacturing across various industries, facilitating a comprehensive transformation.

7. The Importance of Smart Manufacturing: In the electronics manufacturing industry, characterized by small, irregular, and variable components, many process links still require human intervention, making automation challenging. However, with advances in machine learning and new sensors, robots and software systems are becoming increasingly capable, expanding the automation market in the electronics industry.

8. The manufacturing industry is progressing towards Industry 4.0, with new models offering higher production efficiency and lower costs. In the future, the same production equipment will be able to rapidly produce diverse products, personalized demands will be further accommodated, and on-demand production will become the norm. Factories will no longer face inventory risks, and customers will be able to customize products instantly to meet their specific needs.

9. The essence of intelligent manufacturing is to apply human wisdom to the manufacturing industry, endowing China’s industry and manufacturing sectors with their own intelligent capabilities. Intelligent manufacturing not only addresses intelligent production challenges but also drives the development of all industries from the foundational level—such as PCBA patch and proofing manufacturing intelligence. This will foster a transition to a new economic model, shifting from traditional market economies focused on assets and capital to smart economies emphasizing data and operations. This evolution represents a transformative process from traditional asset-heavy models to a smart economy with lighter capital requirements and data-driven operations.

2. With the rise of technologies like the Internet of Things and cloud computing, the global manufacturing industry is transitioning to an era of digitization and intelligence.

3. In particular, the development of intelligent manufacturing for PCBA patch proofing—an essential technology for the Internet of Things—is also driving advancements in other industries.

4. However, overall, China’s manufacturing industry is large but not strong, with relatively weak independent innovation capabilities, high resource consumption, excessive low-end production capacity, and a clear shortage of high-end supply.

5. The entire industry remains at the middle and low end of the global manufacturing chain.

6. The Nineteenth National Congress report highlighted the need to accelerate the development of the manufacturing industry, promote advanced manufacturing, and integrate the Internet, big data, artificial intelligence, and the real economy.

7. Given the current context of domestic energy transitions and intensifying international competition, advancing intelligent manufacturing is crucial for achieving the strategic goal of becoming an industrial power.

1. Without automation, intelligence cannot be achieved. To realize intelligent manufacturing, we must integrate process technology, material technology, equipment technology, and fundamental manufacturing technology. The future competition will center around products, services, and increasingly, costs. By optimizing production processes and incorporating smart equipment, intelligent manufacturing will enable companies to significantly reduce production, operation, and management costs through advanced computing models and automated operations. This will improve production efficiency and enhance overall competitiveness.

2. We not only anticipate the development of smart manufacturing but are committed to advancing it continually. Our strategy includes “going out” to embrace external opportunities, share knowledge, and pursue win-win cooperation. As previously mentioned, for China to transition from a major manufacturing country to a manufacturing powerhouse, it must vigorously develop smart manufacturing both within enterprises and at the foundational level of the industry. For instance, the intelligent manufacturing of PCBA patch proofing has already begun.

3. The shift from poverty to change, from change to commonality, and from commonality to strength is evident. With the gradual progress in the PCBA manufacturing industry, China’s manufacturing will once again achieve self-sufficiency, eliminating the need to import items such as toilets from Japan, which are neither convenient nor aesthetically pleasing. Chinese-made toilets now offer comfort and functionality, and you no longer need to rely on friends to bring back bone-cutting knives from Germany—Chinese kitchen knives now handle bone cutting effortlessly. In the future, Chinese companies will place greater emphasis on product quality and service: ensuring the highest quality and meticulous service.

4. As the middle class continues to expand, manufacturing companies that do not evolve in terms of quality and service will face significant challenges.

5. New Consumption Concepts: The implementation of Made in China 2025 will greatly enhance product quality. Consequently, production will shift from being reliant solely on worker skills and emotions to utilizing precise and stable automated machinery, integrated software and hardware production methods, and a scientifically managed system.

6. The high-level integration of informatization and industrialization involves driving industrialization with informatization, promoting informatization through industrialization, and charting a new path for industrialization. The core of this integration is to use informatization as a support point and to pursue a sustainable and rapid development model. This involves comprehensively implementing the strategic goals of Made in China 2025, from basic PCBA patch proofing to intelligent manufacturing across various industries, facilitating a comprehensive transformation.

7. The Importance of Smart Manufacturing: In the electronics manufacturing industry, characterized by small, irregular, and variable components, many process links still require human intervention, making automation challenging. However, with advances in machine learning and new sensors, robots and software systems are becoming increasingly capable, expanding the automation market in the electronics industry.

8. The manufacturing industry is progressing towards Industry 4.0, with new models offering higher production efficiency and lower costs. In the future, the same production equipment will be able to rapidly produce diverse products, personalized demands will be further accommodated, and on-demand production will become the norm. Factories will no longer face inventory risks, and customers will be able to customize products instantly to meet their specific needs.

9. The essence of intelligent manufacturing is to apply human wisdom to the manufacturing industry, endowing China’s industry and manufacturing sectors with their own intelligent capabilities. Intelligent manufacturing not only addresses intelligent production challenges but also drives the development of all industries from the foundational level—such as PCBA patch and proofing manufacturing intelligence. This will foster a transition to a new economic model, shifting from traditional market economies focused on assets and capital to smart economies emphasizing data and operations. This evolution represents a transformative process from traditional asset-heavy models to a smart economy with lighter capital requirements and data-driven operations.