The Technical Aspects of TCD Process in PCB Fabrication

-

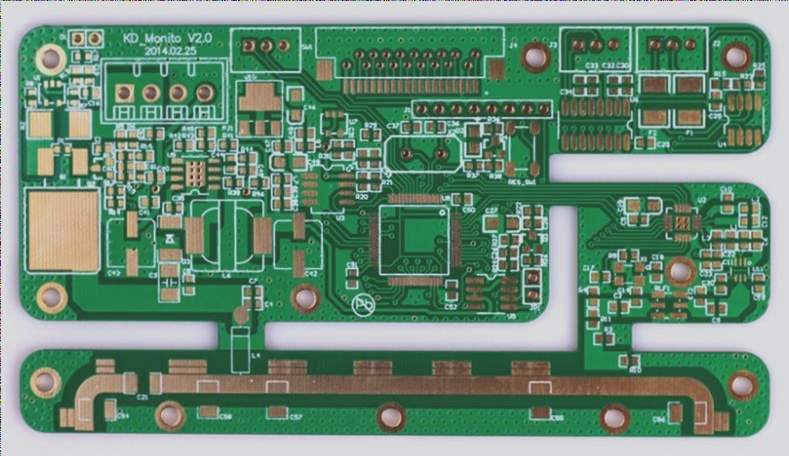

Plug Hole Technology

One crucial step in the TCD process is utilizing Plug Hole Technology. This involves filling inner through holes with plugging oil before applying thermosetting ink through screen printing. Failure to plug the holes properly can lead to depressions and air bubbles, affecting circuit production and the PCB’s ability to pass thermal shock tests.

-

Screen Printing Technology

Quality screen printing is essential in TCD technology. It is vital to control ink thickness, ensure ink flatness, manage ink expansion and contraction, and control board surface warpage to meet customer specifications.

-

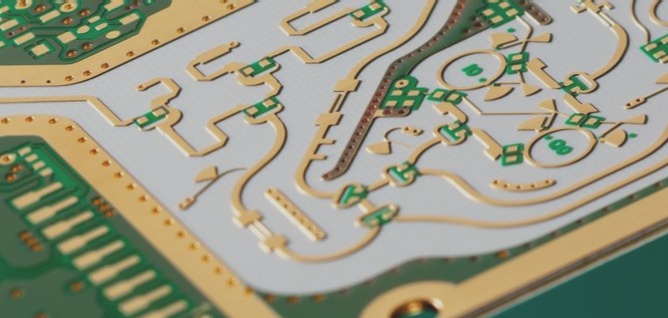

Surface Roughening Technology of Ink Layer

Proper surface roughening of the ink layer is necessary to establish a strong bond between the ink layer and the copper layer after Plated Through Hole (PTH) formation. Wire tension should exceed ≥1.0kg/cm after circuit formation on the copper layer.

-

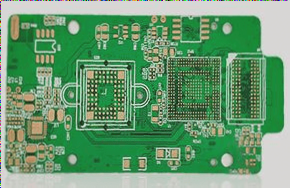

Electroless Copper Sinking Technology

Electroless copper sinking on the ink layer’s surface differs significantly from traditional hole metallization in PCBs. It requires uniform copper distribution across blind holes and through-hole surfaces. Maintaining proper line tension between ink layers post-electroplating is crucial to prevent delamination after thermal shock tests.