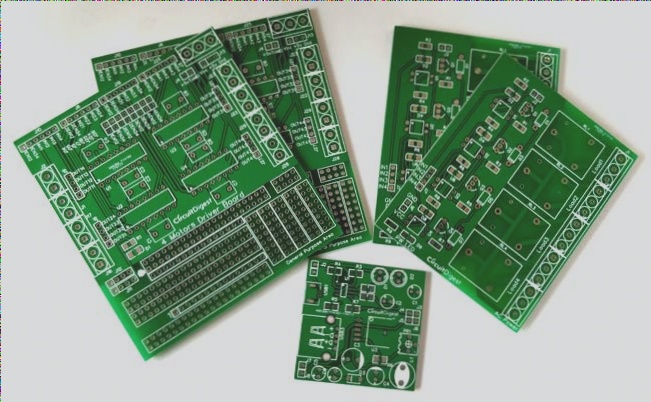

1. Commonly used home appliance control board design and development is a type of circuit board.

2. Although its application range is not as broad as that of general circuit boards, it is smarter and more automated.

3. In simple terms, a circuit board that serves a control function can be referred to as a PCB control board.

4. The control panel is a core component of various household appliances, with many specific program functions executed by this part.

5. In a sense, the quality and longevity of household appliances are dictated by the quality of the control panel.

6. Ensuring the quality of control panels is fundamental to the survival and growth of major control panel companies.

7. Selecting a high-quality control board is crucial for home appliance companies to improve PCB product quality and enhance market competitiveness.

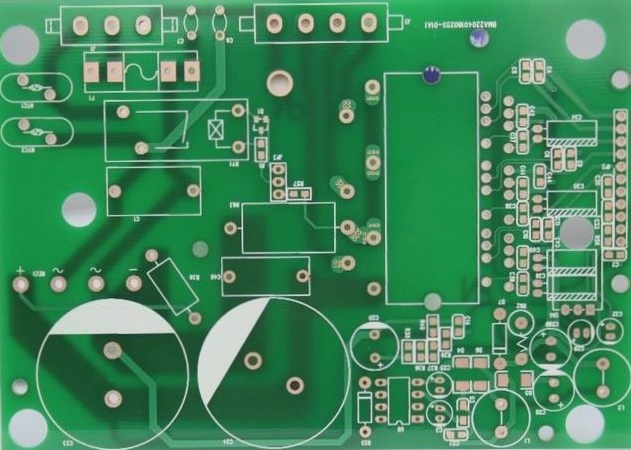

1. As the Internet of Things (IoT) becomes increasingly popular, home appliance control panels are also incorporating IoT technology. This includes not only household appliances but also various commercial control panels. These can be broadly categorized as follows: home appliance IoT controllers, smart home control systems, RFID wireless curtain control panels, cabinet heating and cooling air conditioning PCB control panels, electric water heater control panels, household range hood control panels, washing machine control panels, humidifier control panels, dishwasher control panels, commercial soybean milk machine control panels, ceramic stove control panels, automatic door control panels, electric lock control panels, and intelligent access control systems.

2. Currently, the PCB control panel industry lacks clear subdivision and can be broadly categorized into major appliance control panels (such as those for washing machines, air conditioners, and range hoods) and small household appliance control panels (such as those for soy milk machines, induction cookers, dishwashers, and pressure cookers). Many manufacturers producing small household appliance control panels engage in extensive processing and can produce various types of control panels, which hinders differentiated competition. Nevertheless, with ongoing technological advancements and deeper economic globalization, some leading control panel manufacturers have introduced advanced technologies and innovative production concepts. For instance, Jinxin Electronics’ induction cooker control board employs German automatic phase lock technology and automatic working frequency tracking, featuring IGBT soft start, overheat protection, overcurrent protection, surge current protection, surge voltage protection, undervoltage and over-voltage protection, short-circuit protection, and a response time of ≤0.2µs, significantly enhancing the control board’s quality and lifespan.

3. The smart controller industry is highly reliant on PCB technology, where technological innovation and design capabilities are crucial for competitive advantage. However, after visiting and analyzing various companies, it appears that for many small and medium-sized intelligent controller firms, technology and design alone may not ensure survival. Instead, lower prices, reduced costs, and high production volume often become the primary factors for these companies.

4. The past two years have seen rapid advancements in smart home appliances. Innovations range from “cloud” appliances to “net” technology and the popularization of new concepts, driving demand in the PCB market. As home appliance accessories, especially when balancing PCB technology with cost considerations, small and medium-sized intelligent control board companies face significant challenges. Navigating competition and establishing a strong brand presence will be crucial for these companies to succeed.

2. Although its application range is not as broad as that of general circuit boards, it is smarter and more automated.

3. In simple terms, a circuit board that serves a control function can be referred to as a PCB control board.

4. The control panel is a core component of various household appliances, with many specific program functions executed by this part.

5. In a sense, the quality and longevity of household appliances are dictated by the quality of the control panel.

6. Ensuring the quality of control panels is fundamental to the survival and growth of major control panel companies.

7. Selecting a high-quality control board is crucial for home appliance companies to improve PCB product quality and enhance market competitiveness.

1. As the Internet of Things (IoT) becomes increasingly popular, home appliance control panels are also incorporating IoT technology. This includes not only household appliances but also various commercial control panels. These can be broadly categorized as follows: home appliance IoT controllers, smart home control systems, RFID wireless curtain control panels, cabinet heating and cooling air conditioning PCB control panels, electric water heater control panels, household range hood control panels, washing machine control panels, humidifier control panels, dishwasher control panels, commercial soybean milk machine control panels, ceramic stove control panels, automatic door control panels, electric lock control panels, and intelligent access control systems.

2. Currently, the PCB control panel industry lacks clear subdivision and can be broadly categorized into major appliance control panels (such as those for washing machines, air conditioners, and range hoods) and small household appliance control panels (such as those for soy milk machines, induction cookers, dishwashers, and pressure cookers). Many manufacturers producing small household appliance control panels engage in extensive processing and can produce various types of control panels, which hinders differentiated competition. Nevertheless, with ongoing technological advancements and deeper economic globalization, some leading control panel manufacturers have introduced advanced technologies and innovative production concepts. For instance, Jinxin Electronics’ induction cooker control board employs German automatic phase lock technology and automatic working frequency tracking, featuring IGBT soft start, overheat protection, overcurrent protection, surge current protection, surge voltage protection, undervoltage and over-voltage protection, short-circuit protection, and a response time of ≤0.2µs, significantly enhancing the control board’s quality and lifespan.

3. The smart controller industry is highly reliant on PCB technology, where technological innovation and design capabilities are crucial for competitive advantage. However, after visiting and analyzing various companies, it appears that for many small and medium-sized intelligent controller firms, technology and design alone may not ensure survival. Instead, lower prices, reduced costs, and high production volume often become the primary factors for these companies.

4. The past two years have seen rapid advancements in smart home appliances. Innovations range from “cloud” appliances to “net” technology and the popularization of new concepts, driving demand in the PCB market. As home appliance accessories, especially when balancing PCB technology with cost considerations, small and medium-sized intelligent control board companies face significant challenges. Navigating competition and establishing a strong brand presence will be crucial for these companies to succeed.