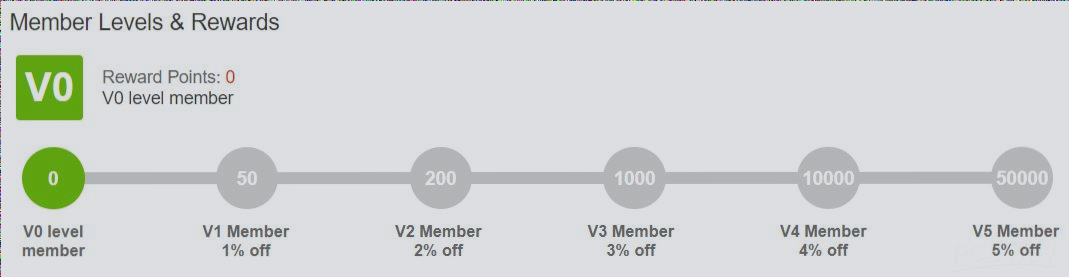

The Evolution of PCB Technology and Market Trends

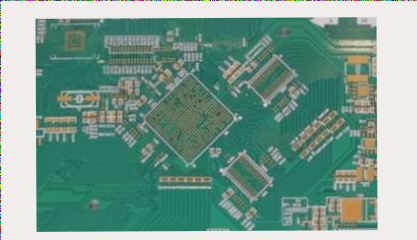

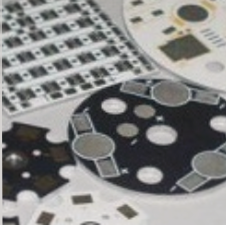

PCB circuit boards, known as the “mother of electronic system products,” play a crucial role in electronic devices. The current trends in electronic products are leaning towards miniaturization, lightweight design, high-speed, and high-frequency performance. These trends are pushing the PCB industry towards higher density, greater integration, and advanced packaging.

High-Density Interconnect (HDI) Boards

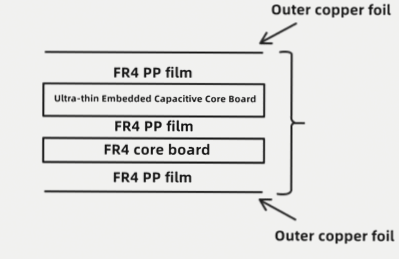

There is a growing demand for high-end boards and HDI (High-Density Interconnect) boards due to the need for long trace lengths, low circuit impedance, and stable performance under high-frequency operations. These boards must support complex functions as electronic technology advances.

The Shift Towards High-Performance PCBs

- High-end PCBs with more than 10 layers are essential for advanced industries like servers and aerospace applications.

- Copper cladding with high performance is becoming a prominent trend in the industry.

- Specialty copper cladding materials, including halogen-free, lead-free, high Tg, high-frequency, and high thermal conductivity variants, are in high demand.

Environmental Concerns and Regulations

Environmental protection is a significant focus in the PCB industry. The use of halogens in PCBs is being restricted globally due to environmental concerns. Research has shown that halogen compounds in electronic products can release harmful substances during incineration.

Halogen-Free Initiatives

- Major international manufacturers are pushing for halogen-free electronics.

- Companies like Sony, Toshiba, Nokia, and Apple are demanding halogen-free boards.

- The compound annual growth rate of halogen-free FR4 boards is projected to be the highest, reaching 21.5% between 2011 and 2016.

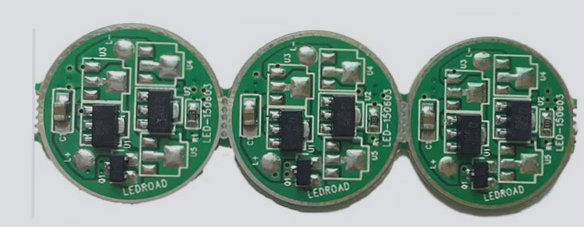

The growth of LED technology has increased the demand for high thermal conductivity copper cladding. Small-pitch LEDs are rapidly penetrating various markets due to their seamless integration and long lifespan.

The Importance of Quality in Automotive PCBs

Automotive PCBs are crucial components in modern vehicles, with strict quality and reliability standards. To ensure durability, these PCBs often use special energy materials to coat copper, making them resistant to extreme conditions.

Meeting Automotive Industry Standards

Automotive electronics require PCBs that can withstand a wide range of challenges, including temperature variations, voltage fluctuations, electromagnetic interference, and vibrations. This necessitates the use of advanced materials like high Tg substrates, CAF materials, thick copper substrates, and ceramics in multilayer PCBs.

Adapting to Demanding Environments

As vehicles operate in diverse climates and conditions, automotive PCBs play a critical role in ensuring the smooth functioning of electronic systems. By utilizing specialized materials, these PCBs can meet the rigorous demands of the automotive industry.

- High Tg substrates enhance thermal stability

- CAF materials provide insulation and reliability

- Thick copper substrates improve conductivity

- Ceramics offer durability for multilayer designs

Enhancing Performance and Reliability

By incorporating these advanced materials, automotive PCBs can deliver superior performance and reliability, making them essential components in modern vehicles.

For more information on automotive PCBs, visit Well Circuits.