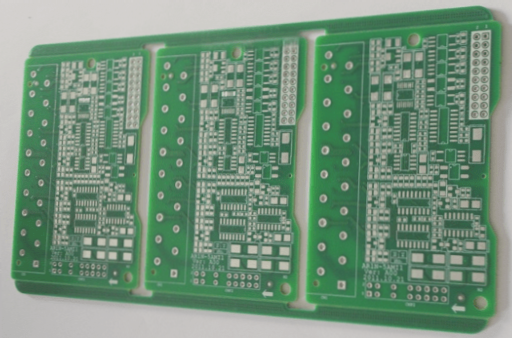

The transportation industry has introduced numerous innovative electronic solutions that leverage complex and highly customized PCBs (Printed Circuit Boards). To ensure safe and reliable transportation, the PCB industry has developed advanced PCB layouts that meet the growing technological demands across various sectors, including road transportation, railways, aerospace, maritime shipping, and automotive markets. However, these advancements also present challenges for PCB manufacturers who must offer high-end customization in terms of material selection, form factors, and sizes. Manufacturers must cater to diverse global customer needs by providing contract manufacturing, commissioning services, or complete turnkey solutions.

Incorporating technologies such as SMT (Surface Mount Technology) and through-hole technology has become essential for efficient PCB manufacturing and assembly processes. The increasing adoption of PCBs in the transportation industry is evident across a variety of applications, including advanced navigation systems, tracking systems, alarm systems, lighting equipment, and other essential electronics in vehicles like cars, trucks, buses, trains, ships, submarines, airplanes, and helicopters. These applications require both standard and multilayer PCBs, featuring lower-pitch BGAs (Ball Grid Arrays) and various types of dielectric materials.

In addition to rigid and flexible PCBs, many OEMs (Original Equipment Manufacturers) and EMS (Electronics Manufacturing Services) providers are playing a significant role in the transportation sector. This article highlights the technological advancements driving the growth of PCBs in the transportation industry, the types of PCBs used in these applications, and the challenges faced by PCB manufacturers and design engineers in this highly demanding field.

Through these innovations and the expertise of PCB manufacturers, the transportation sector continues to evolve, offering smarter, safer, and more efficient systems for modern transportation needs.

### Are New Innovations in the Transportation Industry Related to PCBs?

The transportation industry’s rapid innovations are increasingly intertwined with the advancements in printed circuit board (PCB) technology. As transportation systems evolve, the demand for high-speed, complex PCBs with superior energy delivery and heat management capabilities has surged. These PCBs must support diverse design tools, such as schematic capture, layout design, and simulation methods. Furthermore, cutting-edge 3D modeling and system perception engineering are being used to track mechanisms within circuit boards, optimizing overall performance.

### PCB Challenges and Solutions for the Transportation Sector

PCB designers face the challenge of developing compact, technology-driven solutions that incorporate multi-functional features such as expanded memory, higher power potential, and enhanced data processing systems. Additionally, they must meet the cost-effectiveness demands of automotive electrical solutions. Overcoming these challenges, new technologies like rigid/flexible PCBs with flexible molding and super High-Density Interconnect (HDI) functionality are proving essential for meeting the transportation industry’s stringent requirements.

### Transportation Technologies Utilizing Advanced PCBs

1. **GPS and Tracking Systems**:

GPS tracking devices have revolutionized transportation, with vehicles transmitting battery data directly to network servers. Rigid/flex PCBs are increasingly prevalent in mini GPS trackers used in various transportation systems. These PCBs are also found in backup alarm systems for trucks, forklifts, electric vehicles, buses, oil tankers, and other heavy-duty vehicles.

2. **Alarm Systems**:

Alarm systems for vehicles, including call alarms, have been enhanced to provide real-time, risk-free warnings. These systems alert drivers to hazards such as disengaged manual brakes, unbuckled seat belts, or low fuel levels. Anti-theft systems, including alarms that lock doors and steering wheels, also rely heavily on PCB technology. As such, anti-theft and automotive alarm circuits make up a significant portion of the PCB market.

3. **Railway Systems**:

In railway transportation, PCBs are integral to innovations like automatic transformer track controllers, which regulate railway signal electronics. Detection devices for train control mechanisms and railway lighting systems, including LED lights on trains, all depend on high-quality PCBs. Multi-layer PCBs, dual-row PTH PCBs, and HDI layer PCBs are commonly used in train communication systems and tracking, ensuring efficient operation across the railway industry.

4. **Maglev Trains and Self-Driving Vehicles**:

As maglev (magnetic levitation) trains gradually replace traditional rail systems, electronic equipment plays an increasingly critical role. In parallel, self-driving cars and electric vehicles (EVs) are enhancing mobility with advanced sensors, navigation systems, and calibrated robots. These innovations require sophisticated PCB solutions to support sensors like torque sensors, accelerometers, and braking system controllers.

5. **Intelligent Road Systems and Traffic Management**:

Intelligent transportation systems (ITS) use PCBs to analyze traffic patterns, monitor tire-ground interactions, and guide drivers with real-time traffic and route information. These systems, often seen in self-driving cars and advanced driver-assistance systems (ADAS), rely on a variety of sensors and PCB components to ensure safety and efficiency.

6. **Other Transportation Applications**:

PCBs are also critical in innovations for subways, ships, submarines, speedboats, and even medical transport systems like ergonomic transportation systems. In these specialized vehicles, PCBs manage everything from onboard systems to environmental control, adding value to the transportation sector in multiple ways.

### Impact on PCB Manufacturing and Prototyping

The increasing demand for innovative transportation technologies has created new opportunities and challenges for PCB manufacturers. High-end customization, superior quality control, and on-time delivery are critical aspects of PCB production in this sector. To meet these needs, efficient supply chain and supplier management are essential. Additionally, PCBs must adhere to international quality standards to ensure reliability and performance in safety-critical applications.

### Conclusion

As transportation technology continues to evolve, the role of PCBs in supporting these innovations will only grow. From GPS tracking devices to intelligent road systems and advanced vehicle sensors, PCBs are essential to the functionality of modern transportation. As designers overcome challenges related to cost, size, and performance, the transportation industry’s reliance on advanced PCB solutions will continue to shape the future of mobility.

Incorporating technologies such as SMT (Surface Mount Technology) and through-hole technology has become essential for efficient PCB manufacturing and assembly processes. The increasing adoption of PCBs in the transportation industry is evident across a variety of applications, including advanced navigation systems, tracking systems, alarm systems, lighting equipment, and other essential electronics in vehicles like cars, trucks, buses, trains, ships, submarines, airplanes, and helicopters. These applications require both standard and multilayer PCBs, featuring lower-pitch BGAs (Ball Grid Arrays) and various types of dielectric materials.

In addition to rigid and flexible PCBs, many OEMs (Original Equipment Manufacturers) and EMS (Electronics Manufacturing Services) providers are playing a significant role in the transportation sector. This article highlights the technological advancements driving the growth of PCBs in the transportation industry, the types of PCBs used in these applications, and the challenges faced by PCB manufacturers and design engineers in this highly demanding field.

Through these innovations and the expertise of PCB manufacturers, the transportation sector continues to evolve, offering smarter, safer, and more efficient systems for modern transportation needs.

### Are New Innovations in the Transportation Industry Related to PCBs?

The transportation industry’s rapid innovations are increasingly intertwined with the advancements in printed circuit board (PCB) technology. As transportation systems evolve, the demand for high-speed, complex PCBs with superior energy delivery and heat management capabilities has surged. These PCBs must support diverse design tools, such as schematic capture, layout design, and simulation methods. Furthermore, cutting-edge 3D modeling and system perception engineering are being used to track mechanisms within circuit boards, optimizing overall performance.

### PCB Challenges and Solutions for the Transportation Sector

PCB designers face the challenge of developing compact, technology-driven solutions that incorporate multi-functional features such as expanded memory, higher power potential, and enhanced data processing systems. Additionally, they must meet the cost-effectiveness demands of automotive electrical solutions. Overcoming these challenges, new technologies like rigid/flexible PCBs with flexible molding and super High-Density Interconnect (HDI) functionality are proving essential for meeting the transportation industry’s stringent requirements.

### Transportation Technologies Utilizing Advanced PCBs

1. **GPS and Tracking Systems**:

GPS tracking devices have revolutionized transportation, with vehicles transmitting battery data directly to network servers. Rigid/flex PCBs are increasingly prevalent in mini GPS trackers used in various transportation systems. These PCBs are also found in backup alarm systems for trucks, forklifts, electric vehicles, buses, oil tankers, and other heavy-duty vehicles.

2. **Alarm Systems**:

Alarm systems for vehicles, including call alarms, have been enhanced to provide real-time, risk-free warnings. These systems alert drivers to hazards such as disengaged manual brakes, unbuckled seat belts, or low fuel levels. Anti-theft systems, including alarms that lock doors and steering wheels, also rely heavily on PCB technology. As such, anti-theft and automotive alarm circuits make up a significant portion of the PCB market.

3. **Railway Systems**:

In railway transportation, PCBs are integral to innovations like automatic transformer track controllers, which regulate railway signal electronics. Detection devices for train control mechanisms and railway lighting systems, including LED lights on trains, all depend on high-quality PCBs. Multi-layer PCBs, dual-row PTH PCBs, and HDI layer PCBs are commonly used in train communication systems and tracking, ensuring efficient operation across the railway industry.

4. **Maglev Trains and Self-Driving Vehicles**:

As maglev (magnetic levitation) trains gradually replace traditional rail systems, electronic equipment plays an increasingly critical role. In parallel, self-driving cars and electric vehicles (EVs) are enhancing mobility with advanced sensors, navigation systems, and calibrated robots. These innovations require sophisticated PCB solutions to support sensors like torque sensors, accelerometers, and braking system controllers.

5. **Intelligent Road Systems and Traffic Management**:

Intelligent transportation systems (ITS) use PCBs to analyze traffic patterns, monitor tire-ground interactions, and guide drivers with real-time traffic and route information. These systems, often seen in self-driving cars and advanced driver-assistance systems (ADAS), rely on a variety of sensors and PCB components to ensure safety and efficiency.

6. **Other Transportation Applications**:

PCBs are also critical in innovations for subways, ships, submarines, speedboats, and even medical transport systems like ergonomic transportation systems. In these specialized vehicles, PCBs manage everything from onboard systems to environmental control, adding value to the transportation sector in multiple ways.

### Impact on PCB Manufacturing and Prototyping

The increasing demand for innovative transportation technologies has created new opportunities and challenges for PCB manufacturers. High-end customization, superior quality control, and on-time delivery are critical aspects of PCB production in this sector. To meet these needs, efficient supply chain and supplier management are essential. Additionally, PCBs must adhere to international quality standards to ensure reliability and performance in safety-critical applications.

### Conclusion

As transportation technology continues to evolve, the role of PCBs in supporting these innovations will only grow. From GPS tracking devices to intelligent road systems and advanced vehicle sensors, PCBs are essential to the functionality of modern transportation. As designers overcome challenges related to cost, size, and performance, the transportation industry’s reliance on advanced PCB solutions will continue to shape the future of mobility.

If you have any questions about PCB or PCBA, feel free to reach out to me at info@wellcircuits.com.