Automated Optical Inspection (AOI) in SMT Assembly Lines

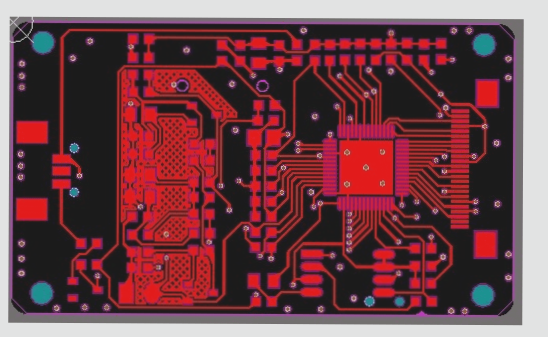

AOI technology has revolutionized the SMT assembly process, replacing traditional manual inspections with advanced imaging systems. By comparing tested objects to standard images, AOI detects discrepancies and ensures quality control.

Evolution of AOI Technology

- Originally used for surface printing inspections after IC packaging, AOI now examines component assembly on PCBs and verifies solder paste integrity.

- Technological advancements have expanded AOI’s capabilities, including improved detection of IC pin misalignments and enhanced camera angles for hidden components.

Advantages and Limitations

AOI offers unparalleled precision in evaluating SMT components, surpassing human visual inspections in accuracy. However, its effectiveness is primarily limited to surface-level assessments, potentially missing defects in obscured or edge areas.

Challenges and Future Prospects

While AOI technology continues to advance, achieving a flawless 100% inspection rate remains a challenge. Enhancements in AI algorithms and imaging systems aim to overcome these limitations and further improve inspection accuracy.