Introduction:

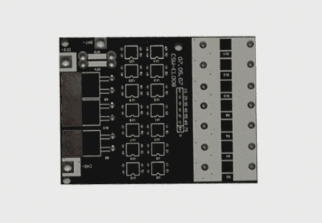

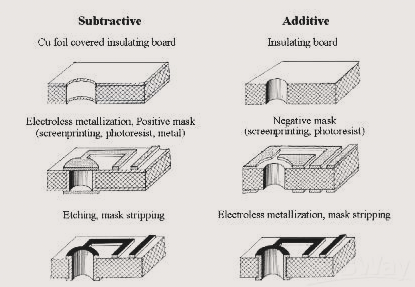

Surface-mount technology (SMT) is a method of producing electronic circuits where the components are directly mounted onto the surface of printed circuit boards (PCBs). The resulting device is known as a surface-mount device (SMD). This technique has largely replaced through-hole technology, which involves inserting components with wire leads into holes on the circuit board. However, both methods can coexist on the same PCB, with through-hole technology typically used for components that are unsuitable for surface mounting, such as large transformers and heat-sinked power semiconductors.

Advantages of SMT:

- 1) Miniaturization

SMT components are significantly smaller than their through-hole counterparts, typically reducing size and volume by 60%-70%, and in some cases, by up to 90%. This also results in a reduction of component weight by 60%-90%.

- 2) High Signal Transmission Speed

SMT components, due to their compact structure and high assembly density (5.5-20 solder joints per square centimeter on double-sided PCBs), enable faster signal transmission with reduced delay. These assemblies are also more resistant to vibration and impact, which is crucial for the ultra-high-speed operation of electronic devices.

- 3) Improved High-Frequency Performance

With no leads or short leads, SMT components reduce the distributed parameters of the circuit, resulting in reduced RF interference and improved high-frequency performance.

- 4) Support for Automated Production

The standardized, serialized, and consistent soldering conditions for chip components facilitate automation, reducing manufacturing defects and improving overall reliability.

- 5) Reduced Material Costs

SMT components benefit from more efficient production equipment and reduced packaging material consumption, lowering the packaging costs compared to through-hole components of the same type and function. As a result, SMT components are generally less expensive.

- 6) Simplified Production Process & Lower Costs

Unlike through-hole components, SMT components do not require lead bending, shaping, or trimming, which shortens the overall manufacturing process and improves efficiency. This results in production cost reductions of up to 30%-50% for circuits with the same functionality.

Disadvantages of SMT:

- Generally, the power is small.

- Small size.

- Easily broken or damaged.

- High soldering technology requirements. Common issues include “pseudo-soldering,” “crater,” soldering leakage, bridges (with tin), “tombstoning,” and other defects.

- Components can easily be dropped or damaged during installation.

- Difficult to visually inspect, making testing challenging.

- Miniaturization and diverse solder joint types complicate the process and inspection.

- Requires significant investment in equipment.

- High technical complexity demands extensive training and learning costs.

- Rapid advancements necessitate continuous updates and adaptations.

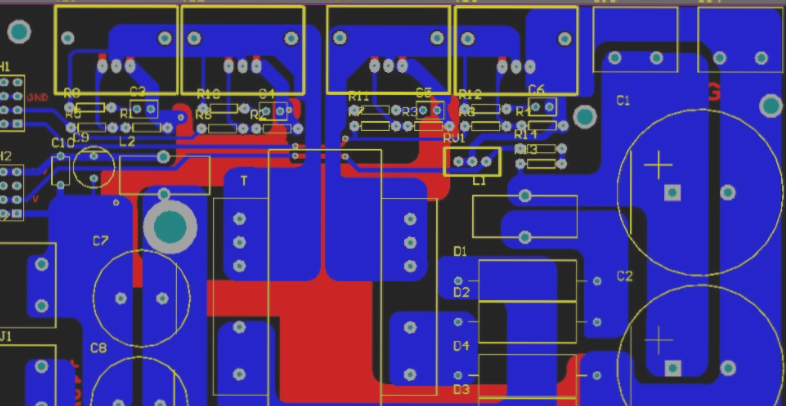

Our state-of-the-art assembly equipment allows us to meet all your PCB assembly needs cost-effectively. Our PCB Assembly capabilities include, but are not limited to, the following. We constantly update our equipment to stay at the forefront of the industry. If your PCB Assembly requirements exceed these capabilities, please contact us at info@wellcircuits.com, and we will respond within 24 hours.

SMT Simple Process: Watch here

If you have any questions about PCB or PCBA, please feel free to contact me at info@wellcircuits.com