Comparing Different 3D Printing Methods: FDM, SLA, and SLS

Fused Deposition Modeling (FDM)

Advantages:

- Simple operation and maintenance

- Cost-effective and eco-friendly

- Compact design for desktop use

- Wide material compatibility

Disadvantages:

- Visible layering on surfaces

- Lamination quality affects part strength

Stereolithography (SLA)

Advantages:

- High precision and smooth surface finish

- Ideal for detailed small parts

- Easy to operate integrated system

Disadvantages:

- Chemically irritating raw materials

- Need for post-processing chemicals

- Sticky material that can stain surroundings

Selective Laser Sintering (SLS)

Advantages:

- Minimal powder residue and strong mechanical properties

- No support material required

Disadvantages:

- Large equipment size

- Need for protective masks during post-processing

- Limited material options and color choices

Consider the unique strengths of each 3D printing method to meet your specific requirements.

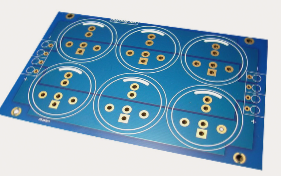

For any inquiries regarding PCBs or PCBA, reach out to us at info@wellcircuits.com.