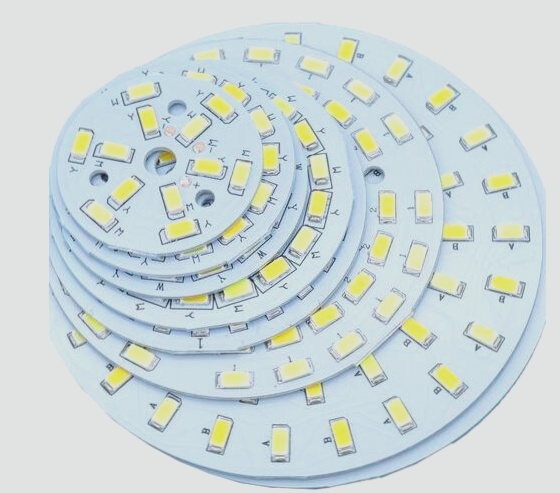

LED Lighting Aluminum PCB: Optimal Thermal Management for High-Power LED Applications

Introduction

LED lighting aluminum PCBs consist of a thin dielectric layer with excellent thermal conductivity and electrical insulation properties, sandwiched between a copper circuit layer and an aluminum PCB. This unique structure effectively dissipates heat while ensuring separation of electronic components from the aluminum PCB.

Advantages of LED Aluminum PCB

- Improved Thermal Conductivity: LED aluminum PCBs offer enhanced thermal conductivity, leading to better heat dissipation and lower LED component temperatures, resulting in extended lifespan and increased reliability.

- Durability and Stability: These PCBs are more durable and mechanically stable, making them ideal for harsh environments and high-power applications, enhancing resistance to impact and vibration.

- Lightweight: LED aluminum PCBs are lightweight, facilitating easy installation and handling, reducing transportation costs, and environmental impact.

- Cost-Effectiveness: In addition to thermal conductivity and durability improvements, LED aluminum PCBs are cost-effective, reducing manufacturing and end-user costs.

Aluminum PCBs for High-Power LED Applications

Aluminum PCBs are commonly used for high-power LED applications due to their excellent heat dissipation capabilities. They are a type of metal core PCB with an aluminum core and insulation layer, effectively dissipating heat, cooling components, and extending component lifespan.

Types of Aluminum PCBs

1. Flexible Aluminum PCBs

Flexible aluminum PCBs offer excellent thermal conductivity, insulation, and flexibility, providing high-performance connections without the need for additional components, saving space and reducing production costs.

2. Mixed Aluminum PCBs

Mixed aluminum PCBs combine non-heat-resistant materials with aluminum matrix metals for improved heat dissipation and rigidity at a lower cost, though with reduced flexibility.

3. Multi-Layer Aluminum PCBs

Multi-layer aluminum PCBs consist of multiple thermal conductive layers with high conductivity, meeting basic heat dissipation needs despite lower heat transfer efficiency.

Benefits of LED Lighting Aluminum PCBs

- Surface mount technology for efficient thermal diffusion

- Reduces product operating temperature

- Improves product power density and reliability

- Extends product service life

- Reduces product volume

- Decreases hardware and assembly costs

LED lighting aluminum PCBs find extensive applications in communication, power, electronics, medical equipment, mechanical equipment, and lighting industries.