Advantages of Multi-layer Circuit Boards in High-Speed PCB Design

- High Assembly Density and Compact Size

- Simplified Routing Process and Enhanced Signal Transmission Speed

- Consistent Low Impedance Path to Ground for High-Frequency Circuits

- Integration of Metal Core Heat Dissipation Layer for High Heat Dissipation Requirements

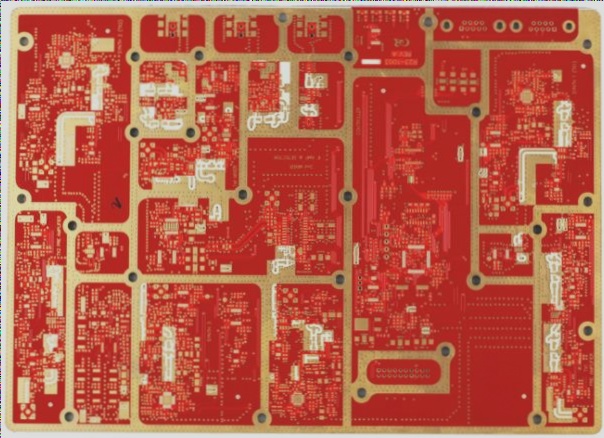

Multi-layer circuit boards offer superior performance compared to single- and double-layer boards. While they come at a higher production cost and longer processing time, the benefits in noise reduction make them a preferred choice. With technological advancements, PCBs with over 100 layers are now used in aerospace instruments and medical equipment.

The most common multi-layer PCBs are four-layer or six-layer boards, with the key difference lying in the additional internal signal layers in the six-layer design. Design flexibility, economic advantages, stable electrical performance, and reliability make multi-layer circuit boards widely used in electronics.

When it comes to PCB layout, consider the size of the PCB, placement of special components like clock components, and overall circuit functions. Proper component placement can improve anti-interference performance.

If you have any PCB manufacturing needs, feel free to contact us.