Key Reasons for Using Flexible FPCs in Medical Devices and Wearable Technology

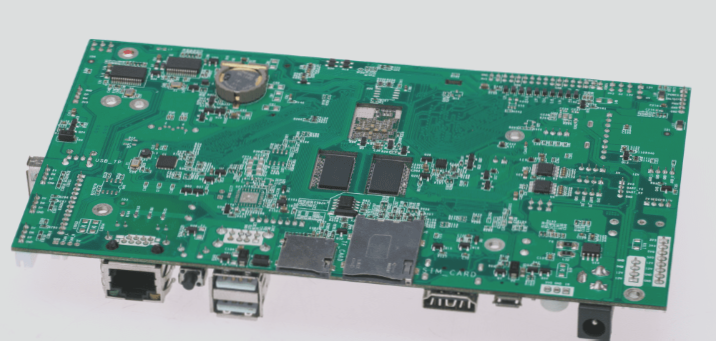

- Miniaturization Trend: Medical and wearable devices require compact designs while maintaining reliable performance. Flexible circuits address challenges faced by FPC manufacturers by enabling the creation of smaller devices.

- Dynamic Bending Advantage: FPCs offer exceptional flexibility and bending capabilities, making them ideal for medical applications where devices undergo expansion and contraction.

- Advantages for Hinge Devices: The flexibility of FPCs presents new design possibilities for healthcare applications, allowing for more compact, durable, and adaptable medical equipment.

Benefits of Flexible FPCs in Medical and Wearable Technology

- Reliability: Flexible circuits reduce potential points of failure, ensuring consistent performance in medical and wearable devices.

- Electrical Reliability: FPC materials are ideal for high-speed signal applications due to their improved dielectric constant and consistent trace width and spacing.

- Space and Weight: The thin and flexible nature of FPCs allows for size reduction in medical equipment and wearable devices, meeting the demand for compact designs in the industry.

Latest Updates:

A recent study published in the Journal of Medical Engineering & Technology highlighted the growing use of flexible FPCs in advanced prosthetic devices. Researchers found that the flexibility and reliability of FPCs significantly improved the comfort and functionality of prosthetics for users.

Furthermore, leading wearable technology companies are incorporating flexible FPCs in their latest smartwatch models to enhance durability and performance. The use of FPCs has enabled these devices to become more lightweight and comfortable for daily wear.