1. Are you aware of the air source requirements for an SMT chip processing workshop?

2. Does the production environment for SMT chip processing have specific requirements? Is a dust-free environment necessary? The detailed requirements include: the plant’s load-bearing capacity, vibration, and noise levels. The load-bearing capacity of the plant floor should exceed 8KN/m2; vibration should be kept under 70dB, with an upper limit of 80dB; noise levels should be controlled within 70dBA. For power supply, the workshop generally requires single-phase AC220V, three-phase AC380V, with the output power of the switching power supply exceeding 1B of functional loss.

3. Are you familiar with the air source requirements for the SMT chip processing workshop?

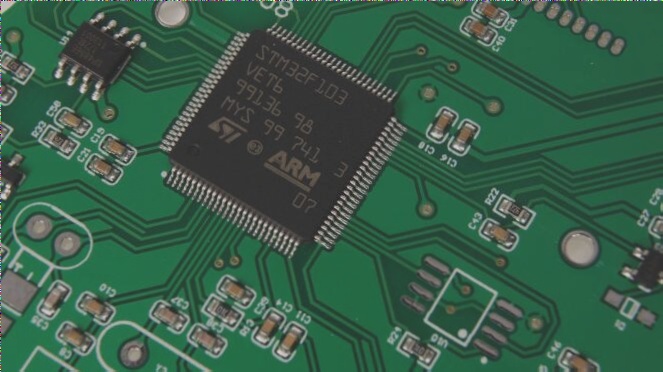

4. SMT chip processing

1. Next are the air source requirements for the SMT patch processing workshop. The air source pressure should be in accordance with equipment specifications. Either the factory’s air source can be used or a separate oil-free compressed air machine may be installed. Generally, the pressure should exceed 5 kg/cm². Clean and dry air is required, so the compressed air must undergo degreasing, dust removal, and sewage treatment. Use stainless steel or pressure-resistant plastic hoses for gas pipelines. The exhaust system also has specific requirements; the reflow oven and wave soldering machine must be equipped with exhaust fans. For a full hot blast stove, the exhaust system pipe’s minimum flow rate is 500 cubic inches per minute.

2. The ideal lighting level in the SMT patch processing workshop should be between 800-1200 LUX, with a minimum of 300 LUX. When lighting is insufficient, install additional lighting in areas for inspection, maintenance, and accurate measurement. The workshop must be cleaned daily, with no dust or corrosive vapors. Cleanliness control should meet a standard of 500,000; the preferred working temperature is 23±3°C, with a general range of 17-28°C, and air humidity should be 45%-70% RH. The workshop’s temperature and humidity should be monitored regularly with appropriate thermometers and hygrometers, and equipped with systems for adjusting these conditions.

3. These are the environmental and temperature requirements for the SMT chip processing workshop. Does this information assist you in any way? If you believe our introduction needs adjustments, feel free to call us for further discussion! Our services include: 2-8 layer circuit board design and wiring; 2-48 layer circuit board production (high TG, halogen-free, HDI, metal base, high-frequency material); 2-8 layer high-precision FPC and soft-hard combination PCB manufacturing; global electronic components purchasing and management; PCBA patch processing (SMT), post-welding, and finished product assembly, among others.

2. Does the production environment for SMT chip processing have specific requirements? Is a dust-free environment necessary? The detailed requirements include: the plant’s load-bearing capacity, vibration, and noise levels. The load-bearing capacity of the plant floor should exceed 8KN/m2; vibration should be kept under 70dB, with an upper limit of 80dB; noise levels should be controlled within 70dBA. For power supply, the workshop generally requires single-phase AC220V, three-phase AC380V, with the output power of the switching power supply exceeding 1B of functional loss.

3. Are you familiar with the air source requirements for the SMT chip processing workshop?

4. SMT chip processing

1. Next are the air source requirements for the SMT patch processing workshop. The air source pressure should be in accordance with equipment specifications. Either the factory’s air source can be used or a separate oil-free compressed air machine may be installed. Generally, the pressure should exceed 5 kg/cm². Clean and dry air is required, so the compressed air must undergo degreasing, dust removal, and sewage treatment. Use stainless steel or pressure-resistant plastic hoses for gas pipelines. The exhaust system also has specific requirements; the reflow oven and wave soldering machine must be equipped with exhaust fans. For a full hot blast stove, the exhaust system pipe’s minimum flow rate is 500 cubic inches per minute.

2. The ideal lighting level in the SMT patch processing workshop should be between 800-1200 LUX, with a minimum of 300 LUX. When lighting is insufficient, install additional lighting in areas for inspection, maintenance, and accurate measurement. The workshop must be cleaned daily, with no dust or corrosive vapors. Cleanliness control should meet a standard of 500,000; the preferred working temperature is 23±3°C, with a general range of 17-28°C, and air humidity should be 45%-70% RH. The workshop’s temperature and humidity should be monitored regularly with appropriate thermometers and hygrometers, and equipped with systems for adjusting these conditions.

3. These are the environmental and temperature requirements for the SMT chip processing workshop. Does this information assist you in any way? If you believe our introduction needs adjustments, feel free to call us for further discussion! Our services include: 2-8 layer circuit board design and wiring; 2-48 layer circuit board production (high TG, halogen-free, HDI, metal base, high-frequency material); 2-8 layer high-precision FPC and soft-hard combination PCB manufacturing; global electronic components purchasing and management; PCBA patch processing (SMT), post-welding, and finished product assembly, among others.