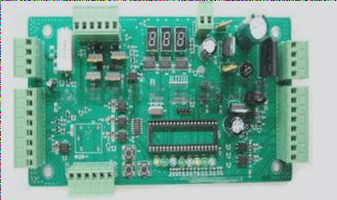

Printed circuit boards vary in terms of the number of layers. The layers that are present in a printed circuit board are either dielectric or made out of conductive material.

The layers can conduct electricity and electric current so when they are assembled into a printed circuit board, they can perform the flow of electrical current.

These layers have a power supply that can run various items ranging from electrically connected supplies and devices. Printed circuit board layers are also known to have a use in the area of industries and medical aspects as well.

However, the only question that keeps on nudging people is how many layers can a PCB have. Well, to know that you need to keep on reading the mentioned details.

Is there anything such as a multilayer printed circuit board?

A lot of people have been thinking for years that how many layers can a PCB have and wonder what it means. However, we need to break it to you that there is no such thing as a multilayer printed circuit board.

The main function of the printed circuit board layers is to function as the main factor that supplies the power and capacity of a particular printed circuit board. Hence, for that reason, people usually think that installing or layering the printed circuit board can be a good way to increase the overall supply of electric current.

The number of layers that you are willing to put or install mainly depends on your budget. If you have enough money, time, and labor then you can add at least 4 to 6 layers to a single printed circuit board.

So, you can easily describe that a multilayer printed circuit board is anything that has more layers than a quantity of 1 or 2. The range of layers that you can install in a single printed circuit board is usually from 6 or between 12 layers.

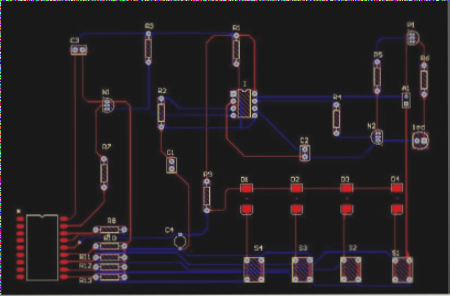

What are the ways to determine the number of layers in PCB design?

With a popular question of how many layers can a PCB have, manufacturers or new engineers want to know the ways to determine those layers too.

There are several ways by the help of which you can be able to know more and help you in the process of discovering. Meanwhile, some of the basic and highlighting ways are mentioned below.

- Choosing the first number of layers

The first and foremost step of the way to determining how many layers can a PCB have is to always use 1 or 2 layers for the printed circuit boards that are built with simplicity. Such layers are used for those PCB design boards that are often manufactured at home or on a smaller scale. In cases where USB or lvds are involved, it is better to stick with 3 to 4 total layers. This way as the steps and work of the printed circuit board gets higher you can eventually increase the number of layers that are installed in it.

However, the main aspect of doing so is usually dependent on your budget. A few things that you need to keep in mind is that there is hardly a difference in the output you are going to get by the installation of 2 or 4 layers in a printed circuit board.

6 layers are used for personal computers, and there is no visible difference between 8 and 10 layers too. The limit where the layers of the majority of printed circuit boards end are up to 12, they are used for heavy work and industry boards.

- Initiate a layout

Now the other step involves in the process of determining how many layers can a PCB have is to start with a proper set layout. The first guide that you need to follow concerning the layout is to start with the top and the bottom of the board.

If by any chance your printed circuit board has a very complex design or works at a high speed then the best option is to add at least up to 2 layers more. This makes them 4 layers that is the top, bottom, and the additional 2 layers.

Your goal is to set everything inside these 4 layers. If you experience that space is needed then the tip that can be useful here is to mix the plan layer. These layers do not have a lot of signals and then add additional 2 more layers to it. This should be kept in your mind that such cases are when you need more spacing.

- Work along with the right ordering

Now, the other thing that you need to keep your focus on is to check and work with the perfect layering order. That means the 12 layers in a printed circuit board provide much power should come at the last. It should be coupled quite rightly.

You can stack up these layers with further additional 2 layers. Then comes the 10 layers lead by 8 layers to 6 layers and then finally 4 layers. So, this is the order that you must follow if you are willing to add up the number of layers in your printed circuit board.

It is important to follow the instructions for adding the layers to your printed circuit board especially if you are a newbie to this work.

Why are the single or even layered/multilayer printed circuit boards opted for?

The majority of the time, printed circuit boards are classified into three types of categories. That are, single side PCB, dour side PCB, and the multilayer PCB respectively. When we talk about multilayer printed circuit boards, we can easily conclude that no number of layers can limit them. The multilayer printed circuit boards can go up to a total of 100 layers as well.

However, the most common number of layers that are often used in a printed circuit board are categorized as even layers. That are either, 4 layers, 6 layers, or 8 layers. Hence, that is the reason the majority of people wonder what is it with the use of an even number of layers in a printed circuit board only.

A 3-layer printed circuit board is known as sometimes used as well. Yet, the main difference between the 3-layered printed circuit board and the 4 layers is that the latter offers more functional advantage and helps in offering more supply of power, and can perform everything that has to do with a 3-layered printed circuit board.

Some of the major reasons why only an even number of layers are used in a printed circuit board are mentioned below.

- The cost of manufacturing

The most important and effective reason why the odd number of layers in printed circuit boards is not preferred is the cost. Usually, the lack of the insulation layers the cost of the printed circuit board can add up.

The price and the cost of the odd number of layers are much higher as compared to the even ones. Moreover, the addition of the odd number of layers in a printed circuit board can also reduce the working of the PCB since it requires a nonstandard process of installation.

Not only that, but it also requires extra work with the outer layer that is made from copper. This process and extra work can cause scratches and damage to the printed circuit board layer.

- Prevention in bending

It is a basic fact that if the printed circuit board starts or can get bent then it can be damaged very easily. So, to prevent that we often do not prefer the use of the odd number of printed circuit board layers since they are more prone to undergo the process of bending.

When the lamination process is done over a multilayer it needs time to cool down. However, if the layers are of odd numbers, then the lamination process can cause them to easily bend.

Meanwhile, one thing that you need to remember is that bending up to some extent is allowed. Yet with such bending the chances of losing excellent work are much higher.

Hence, to make things easier you should develop an understanding that 4 layers are much easier to control as compared to controlling the 3 layered printed circuit board.

Also, the fact that 3 layered printed circuit board has a much greater dimension as compared to 4 layers of the printed circuit board. This can easily describe why the odd number of layers is not preferred in the printed circuit board.

Conclusion

Layering up your printed circuit board is not a crime or is not forbidden to do so. However, it solely depends on your budget and time. Whereas, you need to keep a few things in your mind before adding up the additional layers. Like, as the odd and even ratio and for what purpose do you want the printed circuit board like for normal use or higher industry work?