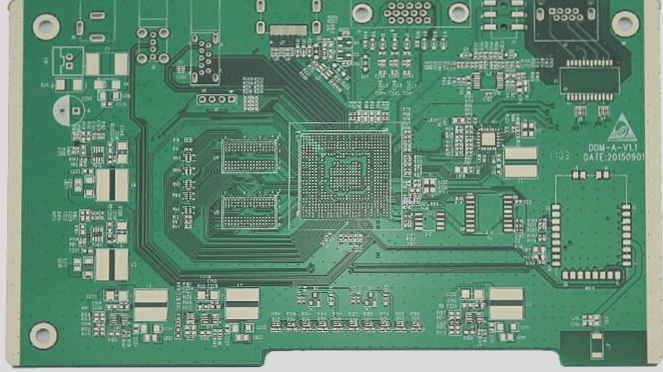

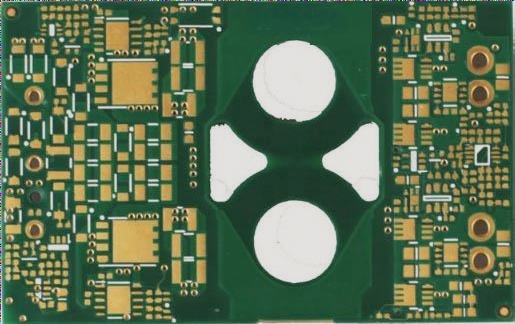

PCB Manufacturing: The Evolution of Silkscreen Technology

Background:

PCB manufacturing has transformed into a cutting-edge high-tech industry, with silkscreen technology playing a crucial role. The rapid advancements in silkscreen technology have revolutionized the electronics industry, making it an essential component in various electronic devices and instruments. Today, silkscreen technology can meet the high-density requirements of PCB production.

Materials:

- 1) Stencil:

The stencil is a vital element in the silkscreen process, controlling ink flow and thickness to ensure durable prints. Interaction between the stencil and photosensitive materials is key for high-quality, high-precision prints. Stencils undergo treatment to enhance adhesion and longevity.

- 2) Light-sensitive Materials:

Common light-sensitive materials like diazo agents and films are used. Diazo emulsion, known for uniform thickness, high resolution, wear resistance, and strong adhesion, is ideal for silkscreen printing on PCBs.

- 3) Stencil Frame:

The material and design of the stencil frame are critical. Aluminum frames are preferred for their strength and reliability, maintaining consistent tension for quality prints.

Silkscreen Printing:

- 1) Silkscreen Printing Process:

The process involves several key steps:

- Prepare soldering film negative

- Punch position holes for the film negative

- Surface cleaning

- Configure printing ink

- Print both sides of the PCB

- Preheat the board

- Exposure

- Develop

- Hot-set

- 2) Key Processes in Silkscreen:

- A) Preheating:

Preheating evaporates ink solvent, making the film non-sticky. Temperature and duration are crucial to prevent degradation of resolution during development.

- B) Exposure:

Proper exposure is critical to avoid image distortion or resolution reduction. Monitoring exposure time with a “light energy integrator” ensures optimal results.

- A) Preheating:

C) Controlling Ink Viscosity:

The viscosity of liquid photoresist ink is crucially influenced by the ratio of hardener to the main agent and the amount of diluent added. Inadequate hardener can lead to imbalanced ink properties. The viscosity changes over time post-mixing:

- Within 30 minutes: Incomplete integration of ink, causing poor flow and potential stencil blockage.

- 30 minutes to 10 hours: Optimal flow and consistency achieved for printing.

- After 10 hours: Ink becomes overly fluid, challenging to print, with diminished gloss.

Excessive thinner can impact ink’s heat resistance and curing abilities. Proper regulation of viscosity is critical for top-notch silkscreen printing quality.

Conclusion:

Silkscreen printing is a straightforward yet precision-demanding process. Adherence to established standards is vital for producing high-quality prints and avoiding defects from mishandling.

For any inquiries regarding PCBs or PCBA, don’t hesitate to reach out to me at info@wellcircuits.com.