PCB Technology Advancements and Manufacturing Techniques

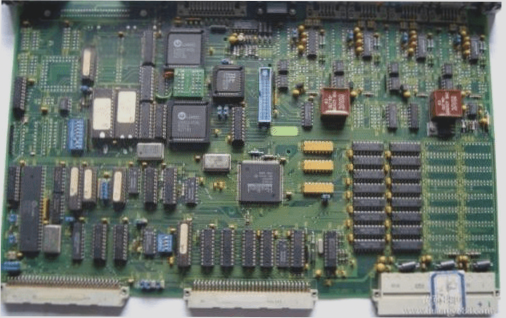

The field of PCB technology is rapidly evolving, bringing forth new challenges and higher requirements. With the increasing density, higher speeds, and demand for miniaturization, traditional manufacturing methods are facing limitations in meeting the needs of modern PCBs.

Exploring Traditional Multilayer PCB Manufacturing

Traditional multilayer PCB manufacturing involves intricate processes, especially in creating outer layer patterns. Two main methods have been traditionally used:

- Pattern Plating and Etching: This method involves coating the PCB surface with a photoresist layer, exposing it to light to create patterns, and then proceeding with plating and etching processes.

- Tenting and Etching: Here, the photoresist covers the lines and holes on the PCB surface, and the exposed copper is etched away to reveal the desired patterns.

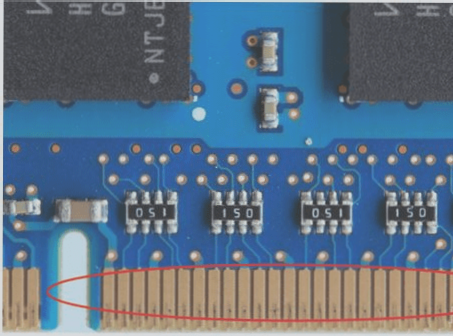

Understanding ED Membranes in PCB Manufacturing

Electrodeposition (ED) membranes play a crucial role in PCB production, offering unique characteristics and a specific deposition mechanism. Key features of ED membranes include:

- Thin and high-density composition.

- Ideal for producing MLBs with strict pattern requirements.

- Exceptional fine line resolution down to 0.025 mm.

- Uniform thickness with strong adhesion, even on imperfect surfaces.

- Efficient production with cost-effective benefits.

For any inquiries regarding PCBs or PCBA services, don’t hesitate to reach out to us at info@wellcircuits.com.