Introduction

Batteries are essential power backup devices in modern technological systems. They play a critical role in powering electric vehicles, home appliances, lighting systems, and many other applications. One of the primary challenges faced by battery users is extending their lifespan to ensure long-term service. Battery failure is a common issue in the consumer industry, often caused by factors such as voltage fluctuations and temperature extremes. A battery is considered to have failed when it can no longer supply or retain the expected voltage. This can be identified by a reduction in the battery’s charge and discharge times, as well as an increase in the temperature of the battery cells above 70°C. This article will explore various methods of battery protection aimed at minimizing battery failures in consumer applications.

Cell Protection

Cell protection is a critical measure used to monitor and ensure that cells operate within predefined limits, thus protecting consumers from losses due to battery failure. Cell protection typically occurs externally to the battery cells, with the Battery Management System (BMS) playing a key role in its implementation. Additionally, cells may be equipped with special safety features such as handling instructions, user protection systems, and design safety measures.

Each type of battery chemistry and application requires a different level of protection. For instance, lithium-ion batteries require specialized control and protection circuits to ensure they remain within safe voltage, temperature, and current limits. The protection circuits in lithium batteries must be capable of discharging high voltages that can accumulate during short circuits, which may occur within microseconds. Lithium-ion cell failures can be particularly hazardous, potentially leading to fires or explosions.

Below are some key issues that battery cell protection must address:

- Excessive charging or discharging currents

- Battery cell short circuits

- Overcharging or overvoltage conditions

- Under-voltage or over-discharging of the battery

- Extreme ambient temperatures

- Excessive internal pressure buildup

- Overheating

- Battery abuse or mishandling

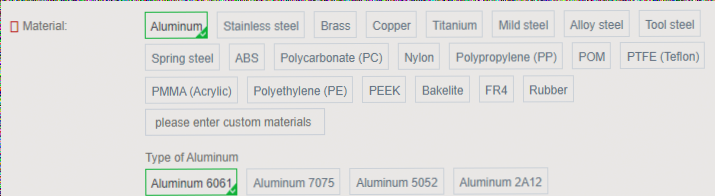

The diagram below illustrates how the cell protection mechanism functions as a constraint, ensuring that the battery operates within a safe working range.

Red zone: The red zone indicates areas where cell manufacturers consider operation to be dangerous, and if the cells enter this zone, they are deemed permanently damaged.

In theory, a cell can function in the remaining areas, but in practice, there is no error margin to safeguard the battery. Therefore, protection devices are used to ensure that the cell operates within the designated green zone.

The white area separating the red and green zones is referred to as the design safety margin.

Figure 1: Cell Protection, Courtesy of Simon Mugo

From the diagram, we can see that there are three protection schemes in place, providing two levels of protection against overcurrent and overtemperature. If one scheme fails, the other serves as a backup safety measure.

Thermal Fuse

Excessive temperatures can cause the failure of battery cells. As a result, most battery protection circuits incorporate thermal fuses that permanently disconnect the battery if the temperature exceeds a specified threshold set by the manufacturer.

Thermistor

Thermistors, though not shown in the diagram, are electrical components whose resistance varies with temperature. Thermistors are classified into two types: Positive Temperature Coefficient (PTC) thermistors, whose resistance increases with temperature, and Negative Temperature Coefficient (NTC) thermistors, whose resistance decreases as temperature rises. Thermistors are used to monitor and protect the circuit by providing temperature compensation, and they can interrupt the charging process or disconnect the battery from the charging circuit when necessary.

Resettable Fuse

As shown in the diagram, a resettable fuse provides protection against overcurrent and overvoltage. It works similarly to a thermal fuse but has the advantage of automatically resetting once the fault condition is cleared or the battery has cooled down. The resettable fuse is triggered when the temperature exceeds a preset level.

Electronic Protection

Batteries are protected against overcurrent by current-sensing devices that react immediately when the current exceeds the upper limit. Since measuring current directly is challenging, these devices typically measure the voltage and resistance in the current path. When the current limit is reached, the sensing device triggers a switch, which interrupts the current flow. This switch can be either a relay or a semiconductor device.

Intelligent Batteries

Intelligent batteries use advanced communication systems to facilitate smart interaction between the battery and its charger. This intelligent charging system enables efficient battery management and ensures optimal performance.

Monitoring

In addition to transmitting important signals to the charger, the intelligent battery charging system can activate warning lights or send notifications to the user regarding the battery’s condition. These monitoring functions are managed by the Battery Management System (BMS).

Circuit Interrupt Devices

Circuit interrupt devices are used to manage cell pressure in smaller batteries. These devices incorporate a small switch that interrupts the current flow if the pressure in the cell exceeds the preset limits.

Pressure, Temperature, and Current Switch

This more complex device detects surges in current and interrupts the current path if excessive pressure or temperature is detected. Unlike traditional disconnect devices, this type of protection resets itself instead of permanently disconnecting the cell when triggered. This feature makes it ideal for small cylindrical cells, such as the 18650 type.

System Isolation

Sometimes, batteries need to be isolated from external faults. This can be achieved through system isolation. For example, in the automotive industry, when an accident occurs, an inertia switch is used to isolate the battery. The battery must incorporate an external switch in the current pathway, which can be triggered by an external signal to disconnect the circuit.

Summary

- Battery cell protection is essential for extending battery life and ensuring reliable performance.

- The protection process begins with monitoring cells to ensure they operate within the predefined safety limits.

- Effective protection should address issues such as overcurrent, short circuits, overcharging, overvoltage, temperature extremes, pressure buildup, overheating, and battery abuse.

- Thermal fuses monitor the temperature and disconnect the battery if excessive heat is detected.

- Thermistors are temperature-sensitive devices used to detect changes in cell temperature.

- Resettable fuses provide overcurrent and overvoltage protection and reset automatically once the issue is resolved.

- Electronic protection uses current sensing devices to protect the battery from overcurrent by interrupting the current flow once a limit is exceeded.

- Intelligent batteries enable smart communication between the charger and the battery for optimal performance.

- Circuit interrupt devices help manage cell pressure and prevent damage due to excessive pressure.

If you have any needs, you can contact me.

info@wellcircuits.com