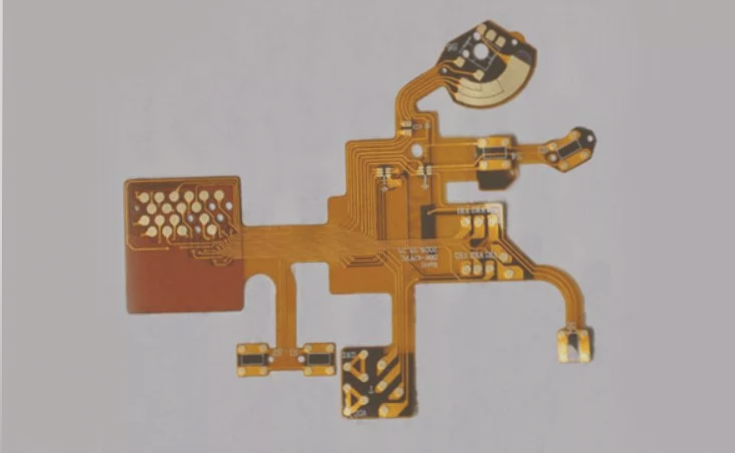

Understanding PCB Layers in Electronics Manufacturing

Printed Circuit Boards (PCBs) play a crucial role in supporting electronic components and facilitating their electrical connections. Before the widespread adoption of PCBs, direct wiring was the primary method of connecting components. However, PCBs have now become the standard in the electronics industry.

The Evolution of PCB Technology

In the early 20th century, Austrian inventor Paul Eisler pioneered the use of PCBs in radios, marking a significant advancement in electronic technology. By 1948, PCBs were officially recognized for commercial use, leading to their widespread adoption in the mid-1950s.

Exploring PCB Layer Functions

As PCBs become more complex, understanding the purpose of each layer is crucial for designers. Altium Designer, for example, offers a comprehensive overview of PCB layers, including signal layers, internal power planes, silkscreen layers, mechanical layers, and masking layers.

Signal Layers

- Top Layer: Also known as the component layer, used for component placement and routing traces.

- Bottom Layer: Referred to as the solder layer for wiring and soldering.

- Mid-Layers: Used for routing signal lines in multilayer boards.

Internal Power Planes

Exclusive to multilayer boards, internal power planes facilitate connections between signal layers and provide power distribution.

Silkscreen Layers

- Top Overlay: Markings for component outlines, labels, and annotations.

- Bottom Overlay: Corresponds to the top layer for additional markings.

Mechanical Layers

- Shape Layer: Defines the PCB outline and dimensions.

- Processing Requirement Form: Specifies manufacturing requirements.

- Component Body Size Information: Contains component size data.

- Footprint Information: Includes footprint data for estimating PCB size.

Masking Layers

Altium Designer offers solder mask and solder paste layers for PCB protection and assembly requirements.