Understanding Multilayer PCBs

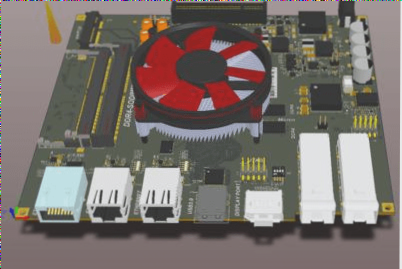

Printed Circuit Boards (PCBs) are essential for electronic devices to function. They consist of electric components and conductive traces built onto a board to connect the components and direct electricity. Multilayer PCBs, a type of PCB, combine different layers to provide increased wiring area.

Exploring Multilayer PCBs

Multilayer PCBs are a combination of single-sided and double-sided PCBs, separated by insulating material like dielectric. They offer a higher number of layers, allowing for more complex designs.

The Number of Layers

Typically, Multilayer PCBs have a minimum of three conductive layers, but can go up to a hundred based on requirements. Most common Multilayer PCBs have 4 to 8 layers, with smartphones potentially having up to 12 layers for complex applications.

Building Multilayer PCBs

To create Multilayer PCBs, layers and materials are joined at high temperatures and pressure to eliminate trapped air. Various materials like ceramic, epoxy glass, or Teflon can be used. The lamination process melts the layers together, forming a solid board.

Considerations for Manufacturing Multilayer PCBs

Factors like signal integrity and power integrity are crucial. Controlled impedance traces and proper copper thickness help maintain current flow and performance. Using a ground plane can shield against magnetic fields, while avoiding 90-degree traces prevents electromagnetic induction issues.

Identifying Layers in Multilayer PCBs

Understanding Multilayer PCBs

In order to identify the individual layers on a Multilayer PCB, using a bright light can help you see the copper planes clearly and analyze the inner layers. Look for layers without crossing lines or paths and check for imprinted layer numbers on the edges.

Drawbacks of Multilayer PCBs

Despite their usefulness, multilayer PCBs come with drawbacks. Consider the cost, longer manufacturing time, and complexity of repairs before choosing them for your project.

Advantages of Multilayer PCBs

Multilayer PCBs offer higher density, enabling greater functionality, capacity, and speed. They facilitate easier electromagnetic shielding, reduce weight by eliminating extensive wiring, save space, and provide increased flexibility.

Applications of Multilayer PCBs

- Computers

- Fiber Optic Receptors

- Data storage

- Signal transmission

- Cell phone transmission

- Cell phone repeaters

- GPS technology

- Industrial controls

- Satellite systems

- Handheld devices

- Test equipment

- X-ray equipment

- Heart monitors

- Cat scan technology

- Atomic accelerators

- Central fire alarm systems

- Fiber optic receptors

- Nuclear detection systems

- Space probe equipment

- Weather analysis

Wellcircuits the Best PCB Manufacturer in China