Fiberglass Cloth: It is one of the raw materials for copper clad laminates. It is woven from fiberglass yarn and accounts for about 40% (thick board) and 25% (thin board) of the cost of the copper clad laminate. Glass fiber cloth manufacturing is similar to weaving companies. The production capacity and quality can be controlled by controlling the speed, and the specifications are relatively single and stable. There has been almost no major change in specifications since World War II. Unlike CCL, the price of fiberglass cloth is most affected by the relationship between supply and demand. In recent years, the price has fluctuated between US$0.50 and US$1.00 per meter. At present, the production capacity of Taiwan and Mainland China accounts for about 70% of the global production capacity. The relationship between upstream and downstream is the key to the operation. The price of a loom is 100,000 to 150,000. Generally, more than 100 units can be produced normally. However, the subsequent heat treatment and chemical treatment equipment require higher funds, reaching tens of millions. The production capacity expansion of cloth is easy and flexible.

Copper Foil: Copper foil is the primary raw material contributing to the majority of the cost of copper clad laminates, accounting for approximately 30% (thick plate) and 50% (thin plate) of the total cost. Therefore, any increase in the price of copper foil serves as the main driver for price hikes in copper clad laminates. Copper foil finds widespread utilization not only within the copper clad laminate industry but also in various other sectors. During periods of industry downturn, copper foil manufacturers have the flexibility to redirect their production towards alternative applications. The fluctuations in the price of copper are directly reflected in the cost of copper foil. With the continuous increase in copper prices, copper foil manufacturers are transferring the cost pressures downstream. High technological barriers within the copper foil industry have resulted in a shortfall in domestic supply. The production of high-grade copper foil necessitates substantial imports and incurs significant expenses for factory establishment.

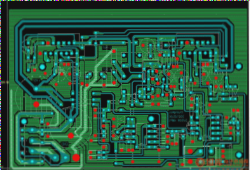

Copper Clad Laminate (CCL for short): CCL is produced by impregnating electronic grade glass fiber cloth with epoxy resin, followed by drying treatment to create a semi-cured bonding sheet. A thin layer of copper foil is then bonded onto single-sided, double-sided, or multi-layer boards through a specialized hot pressing process, constituting the essential raw material for PCBs. The CCL industry requires substantial capital investment, with small-scale enterprises typically investing around 50 million yuan. This industry is characterized by a high level of concentration, with approximately 100 factories operating nationwide. CCL production operates within a cost-driven cyclical framework. Within the upstream and downstream industry structure, CCL possesses significant bargaining power over PCB manufacturers. In instances of robust downstream demand, cost escalations can be transferred to PCB manufacturers, albeit primarily within larger scale operations. Due to the specific application of CCL products, they are exclusively sold to printed circuit board manufacturers. In times of PCB market downturn, pricing adjustments are made to maintain production capacity utilization.

PCB: The printed circuit board (PCB) industry exhibits lower industry concentration compared to its upstream and downstream counterparts. In a fiercely competitive market environment, companies must have strong market positioning and operational efficiency to sustain long-term competitiveness. The establishment of a PCB production line requires an investment exceeding 20 million yuan, while multilayer board production necessitates around 50 million yuan and High Density Interconnect (HDI) production surpasses 200 million yuan. Given the size of the industry, specialized outsourcing services are prevalent for specific processes such as drilling, resulting in surplus supply of low-end products. High-end segments like HDI entail significant capital and labor investments and demand advanced management and technological capabilities, often imposing constraints on capacity expansion.