What is Flexible PCB?

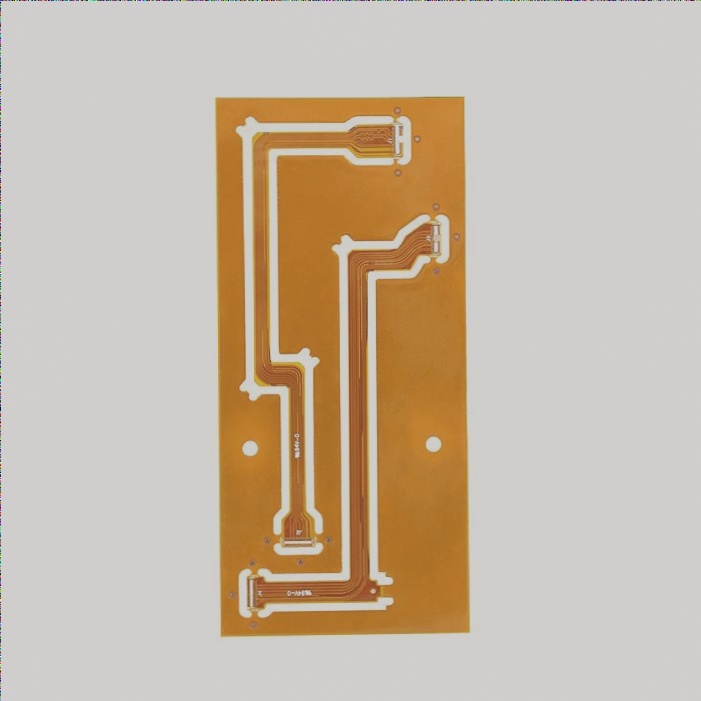

Using flexible circuit boards instead of rigid PCBs is an excellent approach to making flexible electronics. They may be bent and formed into layers, allowing us to employ them in a variety of settings. These are the kind of applications where flexible PCBs excel, and here is where they should be used. Consider a sensor that relies heavily on batteries.

A Flex PCB Thickness may be determined based on its dimensions and kind. A 1.6mm-thick flexible PCB, also known as an EEB (Extruded Etched Board) or a single-sided PCB, is a popular option among PCB manufacturers. Compared to standard 1.8 mm thick boards, they have a smaller footprint. Because of the heavier material, they are more costly. To produce, they are much longer and more difficult to build.

Learn About The Flex PCB’s Bendability/Flexibility

The Flex FCB Thickness you choose will have a big impact on how your device is used. Your application’s mobility and limits might help you estimate how much flexibility is needed.

For long-term usage, it’s a good idea to limit the amount of flex your board experiences. Because of the frequent changes that occur in the environment, this is even more important. Begin by using the following calculation to figure out how much bending room you’ll need:

“Bending deflection” times “board thickness” divided by “radius of gyration” is the formula. This provides you with an approximate idea of how far each element can flex before breaking. Take a look at this as an example:

It is possible to bend 1/10-inch-thick boards to a maximum of.1 inch. It’s necessary to multiply the thickness of the board (.125 inches) by the deflection (.0015625) to obtain the deflection (.0015625). In all directions, the greatest amount of bending the material can take before it snaps or cracks.

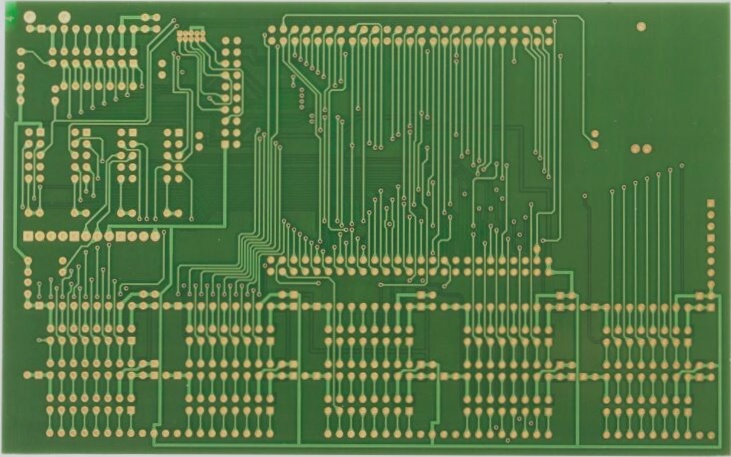

Rigid PCBs are often used in non-flexible environments. It is possible to make them in a variety of thicknesses since they are made of a particular material that is both rigid and sturdy.

The most typical thickness measurements are 1 ounce per square foot (oz/ft2) and 32 ounces per square foot (oz/ft2). As an aside, the decimal weight units for various thicknesses are in certain more modern rigid PCB models’ inscriptions.)

Effects Of PCB Thickness Variation On The Standard

To help you choose the ideal wall thickness for your project, here are some considerations to keep in mind. Materials and substrate thickness are important considerations when deciding on a design.

- The Thickness Of Copper On The Printed Circuit Board

8oz copper PCB is adequate for the majority of electrical devices. The thickness of the copper board has an impact on the look and cost of the PCB as well as the size and flexibility of connections. Copper is the fundamental component of PCBs, and as a result, the copper must be thick enough.

Electronic gadgets requiring very flexible connections may need a bigger copper PCB layer. It is rare for the electrical current to be restricted by thick copper PCBs, as is the case with thinner ones. Heavy boards, on the other hand, are more costly and take up more room in a device.

- Trace The Thickness Of The Printed Circuit Board.

Your device’s total size will be affected by the Flex FCB Thickness of the tracing board. The space needed for shielding and components might be increased by thicker traces. Thinner traces are an alternative for devices that only need a few traces. A five-millimeter trace is recommended for most designs, according to experts.

More copper wire, such as that with a greater diameter, may be used for thicker copper applications. There may be size restrictions imposed by the power ratings and essential components of a device. Choosing a thick copper PCB if your electrical equipment demands high current or crucial components is recommended. Use this measure to help you make purchase choices while analyzing your application.

- Considerations

Choose a PCB board thickness based on the demands of your project. Your board may need to be thicker so that it can handle any damage that may occur throughout a huge job. It is possible that a thinner board, which can be produced more quickly and cheaply, is preferable if your circuit project is tiny.

- Factors Of Quality

There are various elements of quality to consider when purchasing materials for your circuit board.

Prototyping A Flex Pcb With The Right Thickness

PCB thickness and any design issues are determined by the dimensions of your prototype. When working with a prototype, it’s important to keep in mind that a prototype’s level of flexibility is ideal. Flexibility, on the other hand, comes at a price. There are board thickness calculators online that may help you figure out how much board you’ll need to experiment with various flex PCB thicknesses to find which works best for your application.

- Weight Of The Board

As flex printed circuit materials become thicker, so does the total board weight. It may be cheaper to use a thinner material, but it will also make certain assemblies less stable. Although heavier, stiffer objects will be made from denser materials. The board’s electrical properties may be affected by this at times (especially as the board gets hot).

- A Heat Exchanger

Heat sinks are used to remove heat from electronic circuit boards while they are in operation. It is possible to create heat sinks out of any material, even metal. However, a high heat transfer coefficient is required. Low thermal resistance ensures efficient heat transmission. Using this manner, the circuit is kept cool.

We utilize a heat sink to get rid of the heat, but it has to be very effective in terms of thermal resistance and thermal conductivity. PCBs that are thicker can disperse more heat and withstand greater temperatures.

- Cost

It is the cost of the raw materials that will determine the final Flex FCB Thickness pricing. Your PCB’s price per square foot will go higher if you have a lot of layers on it.

- Power

If the PCB is overly thick, the circuit will use more power and may need an additional power source. There will be at least two more traces required for a board with six conductors. Because of this, the power supply can do a better job of supplying the circuit’s components with the appropriate current.

- Reliability

Thinner materials may make a board more flexible and able to handle heavy usage, including bending and crashing. The board will be heavier, and as a result, more expensive.

Advantages Of Flexible PCB

To put it another way: Flex PCBs can be bent to fit in places where stiff ones can’t. Flex PCBs may be used in many applications that call for a board to be mobile, flexible, or even curved, but rigid PCBs can’t.

Many sectors and applications may benefit from the usage of flexible PCBs because of their adaptability. But we may also employ stiff boards, which are typically only used in electrical manufacturing. For these sectors, flexible PCBs are advantageous because they can fit into narrow locations and move about in a way that rigid boards can’t.

- Systems With Adaptable Circuitry

This is a material and circuit design method that allows circuits to bend or curve as necessary. A flexible substrate plus a conductor or semiconductor material or array make up a flex circuit. An easy-to-blend substrate will be found on most flex circuit boards. Other components like resistors and capacitors may still be supported by it.

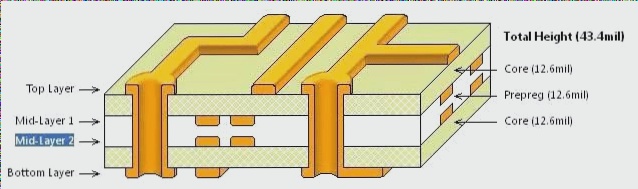

Nonetheless, A variety of flexible circuits may be created by varying substrate thickness and employing different layers for different circuit designs. Flex printed circuits are also made stronger and more lasting by using heavier materials. These components are now supported, and more may be added in the future.

- Lightweight And Compact Design

Flex printed circuit boards have the advantage of being thinner while yet taking up the same amount of area as rigid PCBs. The ability to fit more circuits into a smaller area may be a useful feature when stiff PCBs are out of the question. One of the advantages of employing a flexible circuit board over a rigid one is that it can move naturally with the fingers of the hand.

- Improved Usability

With flexible PCBs, it is possible to create PCBs that are easier to use. As a result, additional soldering areas and component accessibility are provided on PCBs. Soldering mistakes are reduced, and the user is less frustrated as a result. Allowing for more precise movement and better solder connections may also save time.

Conclusion:

In the realm of electronics, flexible PCBs are an option that is often disregarded. The thickness of a printed circuit board (PCB) is critical. This is because the number of layers of circuitry we can fit into the material and the longevity of the board are both determined by this factor. As a result, you must keep track of your board’s thickness and know which thickness to employ for your purposes. Flex FCB Thickness may also be used in specific circumstances, such as environmental sensors that are never exposed to direct sunlight or extreme weather conditions.