The Importance of Power Supply System Design in High-Speed PCB Boards

Understanding the power supply system characteristics of chips, package structures, and PCB boards is crucial for successful high-speed PCB board electronic system design. With the demand for lower supply voltage, faster signal inversion speed, and higher integration, significant investments in power supply system analysis and design are necessary.

The analysis and design of power supply systems (PDS) play a critical role in high-speed circuit design across various industries such as computer, semiconductor, communications, networking, and consumer electronics. As VLSI technology scales down, integrated circuit supply voltages are expected to decrease, with manufacturers transitioning to 90nm technology and supply voltages potentially dropping to 1.2V or lower.

Challenges in power supply system design include managing DC IR voltage drop control and AC dynamic voltage fluctuations. As noise margins decrease, the design of power supply systems faces significant hurdles, especially as the industry moves towards smaller noise margins.

Key Considerations in Power Supply System Design

- Layering of the PCB board

- Shape of the power board layer plane

- Layout of components

- Distribution of vias and pins

In AC analysis, observing the input impedance between power supply grounds is vital for assessing power supply system characteristics. This observation leads to calculating the IR drop in DC analysis. Whether in DC or AC analysis, factors influencing power supply system characteristics include PCB board layering, power board layer plane shape, component layout, and via and pin distribution.

One practical application of power-to-ground input impedance is evaluating the placement of decoupling capacitors on a board. Properly placed decoupling capacitors can suppress circuit board resonance, reduce noise generation, minimize edge radiation, and address electromagnetic compatibility issues, enhancing power supply system reliability and reducing manufacturing costs.

Explore More about PCB Board Power Supply System Design:

For in-depth insights into PCB board power supply system design, visit Well Circuits.

The Importance of Power Supply Systems in High-Speed Circuits

- Power supply system in high-speed circuits is crucial for stable voltage supply to integrated circuit devices.

- Power supply system consists of chip, integrated circuit packaging structure, and PCB board.

- Chip’s power grid includes multiple metal layers with power or ground grids connected by vias.

- Integrated circuit packaging structure resembles a miniaturized PCB board with power or ground planes and decoupling capacitors.

- PCB board contains large-area power and ground planes, decoupling capacitors, and power rectifier module.

- Reducing voltage fluctuations in power supply systems is essential for optimal performance.

DC IR Drop Analysis

- IR voltage drop in chip’s power grid and PCB can impact high-speed system design.

- Factors affecting IR drop include Swiss-Chess structure, Neck-Down structure, and dynamic wiring.

- Design solutions for managing voltage drop range crucial for system performance.

- IR drop analysis integrated into design software helps identify and resolve power supply issues.

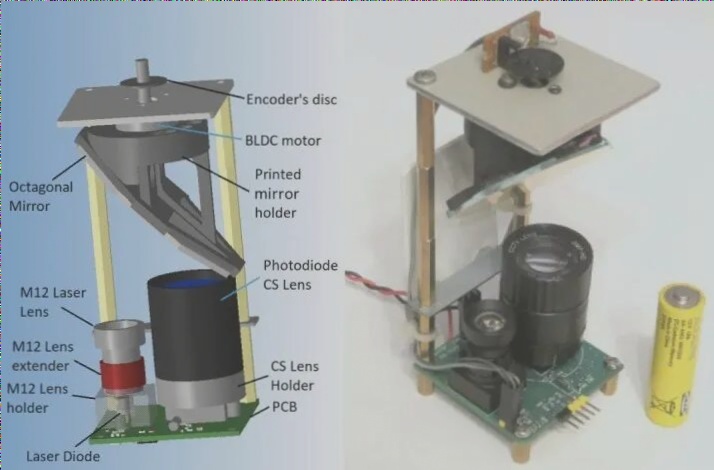

Figure 2 illustrates how IR drop analysis can identify critical voltages and currents in a high-performance PCB power supply system.

AC Power Ground Impedance Analysis

Understanding and optimizing power and ground impedance crucial for high-speed circuit performance.

The Importance of Power Plane Layer in PCB Design

Many are familiar with the concept of a plate capacitor formed by a pair of metal plates in a PCB. While the power plane layer does provide plate capacitance for voltage stability at low frequencies, its behavior becomes more complex as frequency increases.

At higher frequencies, the power plane layer functions as a flat plate transmission line system, where noise and electromagnetic fields propagate between the power supply and ground following transmission line principles. Resonance phenomena occur due to multiple reflections within the PCB board.

For effective design, it is crucial to address impedance issues in the power supply system. Some guidelines include reducing distance between layers, increasing plate size, improving dielectric constants, and using multiple layer pairs.

Decoupling Capacitors for Impedance Control

To further reduce impedance and eliminate resonance peaks, designers commonly place discrete decoupling capacitors on the PCB. These capacitors offer flexibility in adjusting the power supply system’s impedance for lower noise levels.

Optimizing Power Supply System with Decoupling Capacitors

When deciding on decoupling capacitor placement, quantity, and type, designers face various challenges. Utilizing design software and conducting thorough simulations are essential steps in achieving optimal impedance control and noise reduction in PCB power supply systems.

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย