FAQs About PCB Manufacturing

-

Does Copper Foil Thickness Affect LED Service Life?

The thickness of copper foil impacts thermal conductivity of the aluminum substrate, influencing LED service life.

-

Why Are Small Holes Drilled in PCBs?

Small holes, or vias, connect electrical signals between PCB layers.

-

What Temperature is Ideal for Soldering?

Generally, soldering iron temperature ranges from 200 to 300 degrees for different solder joint sizes.

-

Importance of Filming Aluminum Substrates

Unfilmed substrates are prone to scratches and oxidation, impacting manufacturing processes.

-

Soldering LED Beads on Aluminum Substrates

Hand soldering LED beads on aluminum substrates is commonly done using a heating table for precise removal.

-

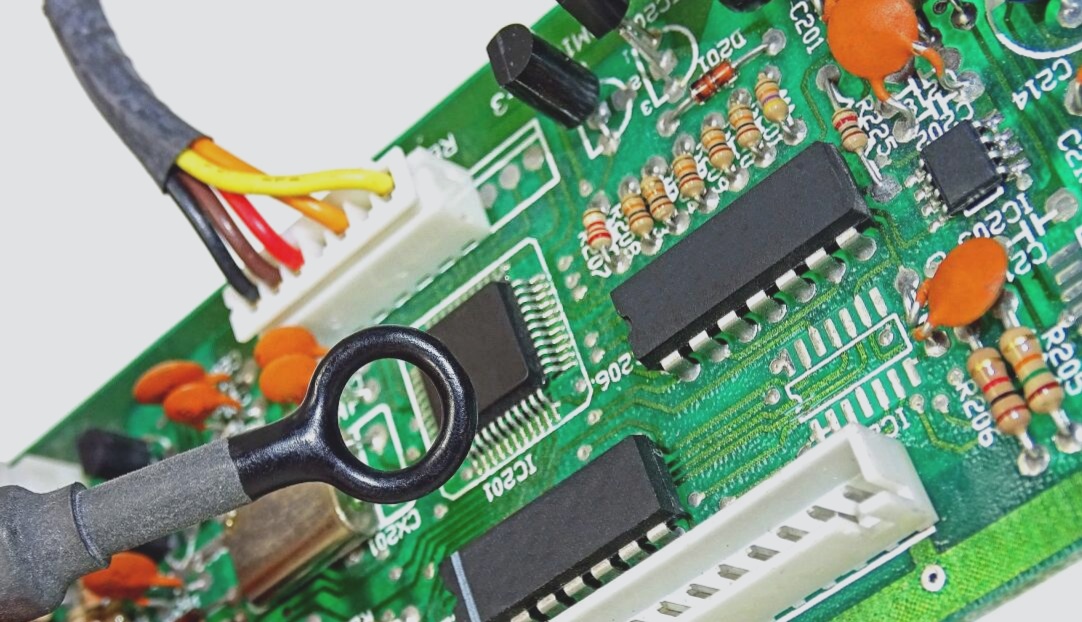

Decoding Circuit Board Labels

Understanding labels like R+, R-, L+, L- helps identify channel polarity and signal directions.

-

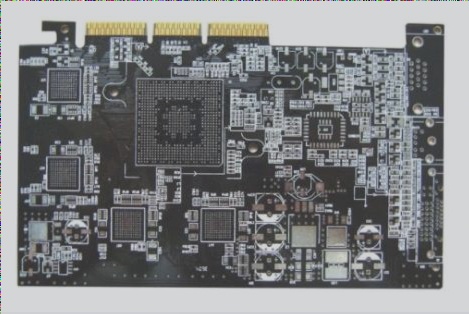

Types of Circuit Boards

From high precision to flexible printed boards, various types like gold-plated and rigid-flex serve different purposes.

-

Main Board PCB Selection

For main switch boards, cost-effective four-layer PCBs are common, with six-layer boards offering enhanced functionality.

-

Laminating Process for Multilayer PCBs

The lamination process bonds conductive layers and insulating materials to create stable multilayer PCBs with prepreg.

WellCircuits Limited specializes in high-precision PCBs including double-sided, multi-layer, and impedance boards, catering to various product needs.